In The Name of the Rose, first published as a book by Umberto Eco in 1980, then adapted in a film starring Sean Connery in 1986, a nonconformist friar investigates mysterious deaths in an isolated abbey to find out that all monks who attempted to read the secret ‘Book of Revelation’ died because the book pages were poisoned. Recent proliferation of electronic touchscreens, which are now widely used on phones, computers, board screens, and other “smart displays”, creates a new unintended route of human exposure to harmful chemical substances during screen touching. Here, after presenting the brief history and chemistry of touchscreens, we explain why per- and polyfluoroalkyl substances (PFAS) and nanomaterials used as anti-smudge coatings are likely to impregnate fingers. Phone addicts, “zombie eaters”, and digit-sucking toddlers are at high risk.

Intuitive touch

Eric Arthur Johnson, an English engineer at the Royal Radar Establishment in Malvern, UK, first described his vision for developing capacitive touch screens in a 1965 paper entitled Touch display—A novel input/output device for computers [1]. Since then, touchscreen displays have transformed the way we interact with electronic devices and gradually gained a dominant presence on today’s consumer electronic devices. Indeed, touchscreens are used on most contemporary mobile computing devices, including smartphones, tablets, smartwatches, and laptop computers. Touch-enabled self-service kiosks are increasingly used in public settings such as schools, libraries, store check-outs, airport check-in's, and fast-food restaurants. They have become an indispensable part of our modern, technology-enabled lives [2]. Market analysis indicates that the current robust growth in the use of touchscreen displays will continue, with the global market for touchscreen displays expected to double its current size and reach over $166 billion USD by 2029 [3]. Touchscreens are very handy; however, how to keep them clean after hundreds of daily finger touches?

Screens that repel smudge

Touchscreen displays generally consist of a cover glass, touch sensors, and a display panel with backlight arranged from top to bottom [4]. One of the early challenges in developing touchscreens for daily use is how to keep their glass surfaces clean. Fingerprints, oil and grease, and smudges left on the surfaces compromise the clarity, appearance, and responsiveness of touchscreen devices. Therefore, the surfaces of touchscreens must be chemically treated to ensure that minimum amounts of fingerprints or other residues are left on the screen surface after finger contact, and that any smudges that do occur should be easily removable [5]. For that, anti-smudge coatings that are optically transparent and chemically inert have become the industry’s standard to create touch surfaces that repel oil, grease, and moisture, and they are easy to apply onto glass screens with fair durability under normal use [6, 7]. With the advancement of material science and processing, these goals have indeed been achieved with a plethora of commercial products offered for manufacturers and do-it-yourself enthusiasts.

Billion-dollar coating

The screen is a main component of many touch-enabled consumer electronic devices, and the application of anti-smudge coatings on the surface of the cover glass is an essential processing step. Apart from smartphones, tablets, and smartwatches, which account for the majority of consumer electronic devices equipped with touchscreens, they have also been incorporated into the design of laptop computer displays, printers, and some newer models of laptop touchpads [8, 9]. Driven by the strong demand for consumer electronics, especially mobile computing devices, the global anti-smudge coating market has already grown into a billion-dollar industry in its own right [10]. However, anti-smudge coatings do contain toxic compounds such as fluorochemicals and nanomaterials, as detailed below [11].

Per- and polyfluoroalkyl substances

The anti-fingerprint ability of electronic touchscreens is mainly gained by the use of fluorochemicals such as per- and polyfluoroalkyl substances (PFAS, Table 1). For example, perfluoropolyethers are commonly used because they form a low surface-energy lubricating layer, resulting from the enrichment of terminal –CF3 groups at the surface [12,13,14], which exhibits hydrophobic and oleophobic properties [15,16,17]. In this vein, coating formulations containing perfluoropolyether–silane, introduced by Daikin, have captured a strong market share [15, 18, 19]. Other major manufacturers of anti-smudge coatings, such as Cytonix and Solvay, also used perfluoropolyether-based formulations [20,21,22].

These substances display toxicity. For instance, safety data of products listed in Table 1 indicate that they can cause irritation to skin and eyes with long-term harmful effects on aquatic organisms [23,24,25]. Moreover, the toxicological information of Daikin’s OPTOOL DSX and OPTOOL DAC-HP coatings shows that these coatings can irritate the skin of rabbits and be harmful to fish and aquatic organisms [23, 25]. Per- and polyfluoroalkyl substances (PFAS) have shown multi-organ toxicity, genotoxicity, reproductive toxicity, neurotoxicity, developmental toxicity, endocrine disruption, and are suspected carcinogens [26,27,28,29]. Recently, concerns have also been raised on fluoropolymers, i.e., a group of fluorinated macromolecules within the class of PFAS, over their impact on environmental and human health throughout their life cycles [30]. Perfluoropolyethers can decompose into fluorocarbon fragments and perfluoroalkoxy radicals, which are known to react with oxygen and moisture in air, leading to the formation of perfluorocarboxylic acids [31,32,33]. Overall, the presence of polyfluorinated substances on touchscreens is of concern regarding their possible transfer to fingers.

Nanomaterials

Liquid screen protectors, used for restoring touchscreen surfaces, contain nanomaterials such as silica nanoparticles (Table 2). When applied on a glass screen, the liquid screen protector penetrates into microscopic surface defects and bonds chemically with the glass substrate. These protectors have oleophobic properties, improving smudge resistance and making the surface smoother and easier to clean, restoring the snappy feel of touchscreen devices [11]. However, nanomaterials such as nanoceramics pose environmental and health risks [44]. Concerning nanosilica, animal studies have evidenced the adverse effects of silica nanoparticles on various organs, showing cardiovascular, skin, respiratory, neurological, liver, genetic, reproductive, and renal toxicities [45,46,47]. Further, rats exposed to silica nanoparticles showed behavioral changes, hepato-renal dysfunction, and hyperlipidemia [48]. Rashidian et al. [49] found that prolonged exposure to silica nanoparticles caused oxidative stress and reproductive issues in adult zebrafish.

Coating wear-off and dermal exposure

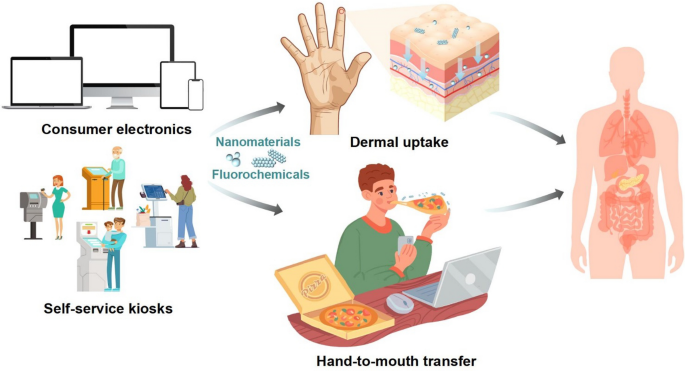

Dermal uptake of coating substances from touchscreen surfaces is a possible route of exposure to fluoropolymers and nanomaterials (Fig. 1). Organofluorine anti-smudge coatings, for instance, are typically applied as thin films on touchscreen surfaces, with thicknesses less than 10–15 nm [17, 34]. This very thin layer is prone to degradation and removal under the finger touch. As a consequence, these oleophobic coatings are by no means “permanent” and the industry has yet to establish a standard to ensure their long-term durability [14, 40, 42]. While an oleophobic coating should be able to sustain a smartphone’s typical 2-year life cycle, misuse, subpar quality, or poor conditions could cause it to wear out within weeks or months of use [12, 57].

Touchscreens on consumer electronic devices and self-service kiosks profoundly changed how humans interact with technologies. These glass touchscreens are chemically treated with a thin layer of coatings on top. These coatings, referred to as anti-smudge coatings or anti-fingerprint coatings, are specially formulated to provide smooth, oleophobic, and easy-to-clean touch surfaces. At the core of these coatings, fluoropolymers, e.g., perfluoropolyethers or nanomaterials, e.g., silica nanoparticles, are the substances that render the screen surfaces smudge-proof by making them hydrophobic (water-repelling) and at the same time, oleophobic (oil-repelling). When users frequently touch these screens, fluoropolymers or nanomaterials may transfer to their fingers and enter the human bodies via dermal uptake and hand-to-mouth transfers during eating, cooking, or nonnutritive sucking by young children

Both fluoropolymer coatings and nanomaterial coatings tend to breakdown under repeated abrasion, causing screens to slowly lose their smudge resistance [12, 53]. The rate of wearing out is controlled by the nature of the object in contact, i.e., soft, hard, or sharp objects, by the contact frequency, e.g., light or heavy use, by the magnitude of forces applied during the contact, and by the micro-environment that the screen coating is exposed to, e.g., ultraviolet light, humidity, acids, oils, alcohols or other ingredients in food and drink, perfumes, or cleaning products. User habits, i.e., sliding forces and contact frequencies, are usually the main factors that determine how fast the coating thins and fails under normal use. In addition, contacts with hard objects such as keys, coins, buttons, or rough clothes on the screen accelerate the wear of the coating. During the mechanical wear process, the Si–C bond connecting perfluoropolyether and silane agent is the weakest and therefore prone to dissociation and potentially forming a new C–O bond, thus compromising the stability of the anti-fingerprint coating [58].

Moreover, using touchscreens in environments with the presence of dust, sand, grease, or moisture can cause the coating to wear out more easily. In the presence of oxygen, water molecules strongly influence the decomposition of perfluoropolyethers, where scission occurs both at the functional ends and the main chain via the C–O bond cleavage [59]. Furthermore, the high surface area of nanosized silica makes such coatings susceptible to contamination by trace amounts of water vapor and volatile organics such as plasticizers, silicone oil, and vacuum grease [60]. Also, exposure to UV light can induce the photodegradation of perfluoropolyethers and cause nanosized silica coating to generate significant amounts of free radicals, which accelerate the breakdown of hydrophobic groups [61, 62]. Finally, the use of solvent-based cleaning products also accelerates the wearing out of anti-fingerprint coatings [63].

“Zombie eaters” and young children

Around the world, screen use during eating is becoming very common. The use of smartphones, tablets, or other electronic devices during eating is particularly common among young people and those who eat alone. A survey of 2,000 adults in the USA found that up to 88% were so-called “zombie eaters” who gazed at or manipulated screens while eating, primarily for reading or sending emails, checking social media, or watching videos [64]. Indeed, screen-distracted eaters are frequently sighted in schools and workplaces, as well as at leisure venues such as food courts, fast-food restaurants, even in parks. In homes, electronic screens are also becoming the new “table staple” at dining tables.

When users come into contact with food after touching screen coatings, the risk of hand-to-mouth transfers of coating debris or associated chemical substances is significantly increased [65, 66]. Also, the use of electronic screens is increasing among young children, e.g., at ages 2–11 when digit sucking is common [67,68,69]. In a survey of nonnutritive sucking behaviors of children between 1 and 8 years of age, Bishara et al. [67] reported that 31% of the surveyed 1-year-old children engaged in digit sucking, with 12% of the surveyed 4- and 5-year-olds and 8% of the surveyed 6- and 7-year-olds showing the same behavior. Some adults also have finger-licking habits when cooking or eating food with sauces and condiments. For them, hand-to-mouth transfers of screen coating residues can easily occur.

Occupational hazards

The processing of organofluorine anti-smudge coatings has raised alerts on worker’s health. Ma et al. [70] reported an incident of acute poisoning in four workers at a Chinese factory applying anti-fingerprint coatings on mobile phone touchscreens, where the coating components and processing aids including perfluoro-1,3-dimethylcyclohexane, hexadecafluoroheptane, perfluoro-hexane, perfluoromethy lopentane, and perfluoro-2-methyl-2-pentene caused acute bronchitis, pulmonary edema, and/or myocarditis in those workers. To our knowledge, this study, which was published in the Chinese Journal of Industrial Hygiene and Occupational Diseases, was among the first reports of acute poisoning due to exposure to touchscreen coating components and processing aids in occupational settings.

60% of the world’s population owns smartphones

The public announcement of the first generation of Apple's iPhone, made by Steve Jobs in January 2007, was the defining moment that gives touchscreens the massive popularity we are seeing today. Now more than seventeen years have passed, global smartphone owners have reached a total user count of 4.9 billion, which represents 60.4% of the world’s population [71]. A 2019 survey among 1,600 young people in the USA showed that over two-thirds of the respondents (69%) owned their smartphones by the age of 12 [72]. During COVID-19, activities such as remote working, online classes, video conferencing, and media streaming grew substantially, which resulted in further increases in daily screen use among the general population [73]. This trend now continues well after the pandemic and will probably persist as the technologies continue to advance. Yet, knowledge gaps exist in the anti-smudge coatings of touchscreen surfaces with respect to their wear-off, dermal uptake, and hand-to-mouth transfer, e.g., by “zombie eaters” and young children, and the potential risks associated with these scenarios in daily activities.

Existing studies on contaminants from screen use have mainly looked at liquid crystal monomers leached from electronic screens [74,75,76]. In this research domain and on a different subject, Li et al. [65] studied the migration of persistent toxic substances from protective cases of mobile phones, noting the risk of hand-to-mouth transfer of these substances. Meanwhile, there is still a lack of data on human exposure to anti-smudge coating debris and potentially their transformational products via dermal uptake and hand-to-mouth transfer. Given the fact that fluoropolymers and nanomaterials are already under intense scrutiny for their adverse effects on environmental and human health, studies are needed to gauge the human exposure and assess the potential health effects resulting from this particular class of substances, especially among vulnerable groups such as young children, pregnant women, and those with occupational exposure. Further, toxicological data on touchscreen coatings used on consumer electronic devices must be provided to the regulators of chemical substances and the general public. Animal studies and cell cultures are needed to elucidate their effects on target organs under “normal use” scenarios with routine exposure or in particular environments.

Safer alternatives

Many have recognized that a world without PFAS is achievable, although the extent to which manufacturers are adopting alternatives remains unclear [77]. In the limited number of scholarly publications currently available, researchers have provided evidence from laboratory studies, proposing fluorine-free polyurethane coatings [78–80], non-fluorinated organosiloxane coatings [81, 82], and castor oil-based coatings [83] as alternatives for use as anti-smudge coatings on touchscreen cover glasses. Liu and co-workers recently reported a highly cross-linked, rigid oxazolidinone structure and a liquid-like molecular coating that demonstrated high hardness, flexibility, transparency, and dynamic omniphobic anti-fouling properties [84]. These studies offer new insights into alternative anti-smudge coatings for glass substrates. Given the widespread use of anti-smudge coatings on touchscreen devices, it is necessary to pursue safer alternatives while conducting more rigorous evaluations of current products regarding their human exposure levels, health risks, and environmental impacts through life-cycle analyses. Although this topic has not yet garnered widespread interest from the research community, the prominence of touchscreens as a primary type of user interfaces on electronic devices suggest that users will ultimately demand safe, durable, and effective anti-smudge coatings to maintain surface cleanliness and optical transparency with minimal risk.

References

Johnson EA (1965) Touch display—a novel input/output device for computers. Electron Lett 1(8):219–220.

Thaper R, Gibson MJ, Mykoniatis K, Sesek R (2023) The role of smart hand held devices—smartphones/iPads/tablets/smartwatches in causing musculoskeletal disorders: a systematic literature review. Int J Ind Ergonom 97:10349. https://doi.org/10.1016/j.ergon.2023.103497

Fortune Business Insights (FBI) (2024) Touch screen display market size, share & COVlD-19 impact analysis, by screen type (resistive touch screens, capacitive touch screens, infrared touch screens, optical, others (surface acoustic wave type displays)), by application (display/digital signage, kiosks, consumer electronics (laptops & tablets and smart television, smartphones & smart wearables)), by end-user (residential, commercial, and industrial), and regional forecast, 2022–2029. https://www.fortunebusinessinsights.com/touch-screen-display-market-105362. Accessed 20 Oct 2024

Ming W, Xie Z, Jiang Z, Chen Y, Zhang G, Xu Y et al (2022) Progress in optical adhesive and lamination process of touch screen in 3C products. J Soc Inf Display 30(12):851–876. https://doi.org/10.1002/jsid.1175

Belhadjamor M, El Mansori M, Belghith S, Mezlini S (2016) Anti-fingerprint properties of engineering surfaces: a review. Surf Eng 34(2):85–120. https://doi.org/10.1080/02670844.2016.1258449

Lu S, Shao J, Martin DC, Li Z, Schwendeman IG (2018) Commercialization of sol–gel based transparent functional coatings. J Sol-Gel Sci Technol 87:105–112. https://doi.org/10.1007/s10971-018-4694-y

Zhong X, Hu H, Yang L, Sheng J, Fu H (2019) Robust hyperbranched polyester-based anti-smudge coatings for self-cleaning, anti-graffiti, and chemical shielding. ACS Appl Mater Interfaces 11(15):14305–14312. https://doi.org/10.1021/acsami.8b22447

ASUSTeK Computer Inc. (ASUS) (2024) Asus-zenbook-14-oled-ux3405. https://www.asus.com.cn/laptops/for-home/zenbook/asus-zenbook-14-oled-ux3405/. Accessed 20 Oct 2024

Huawei Device Co., Ltd (Huawei) (2023) Huawei MateBook 16s 2023. https://consumer.huawei.com/cn/laptops/matebook-16s-2023/. Accessed 20 Oct 2024

BIS Research (2023) Anti-fingerprint coating market—a global and regional analysis, 2023–2032. https://bisresearch.com/industry-report/global-anti-fingerprint-coating-market.html. Accessed 20 Oct 2024

Coatingpaint (2024) Oleophobic coating: versatile and multi-purpose protection. https://www.coatingpaint.com/oleophobic-coating/. Accessed 20 Oct 2024

Liu C, Qing F-L, Huang Y (2023) Transparent and anti-fouling perfluoropolyether coating with superior wear resistance. Appl Surf Sci 620:156813. https://doi.org/10.1016/j.apsusc.2023.156813

Lim SM, Lee MS, Sohn E-H, Lee S-G, Park IJ, Kang HS (2020) Perfluoropolyether-benzophenone as a highly durable, broadband anti-reflection, and anti-contamination coating. Sci Rep 10:15121. https://doi.org/10.1038/s41598-020-72229-7

Osi Specialties (2018) What is hydrophobic oleophobic coating? How long will the hydrophobic oleophobic coating on mobile phones last? http://www.sifoc.com/news/sssytc.html. Accessed 20 Oct 2024

Gopal L, Sudarshan T (2022) Surface engineering for anti-fingerprint applications. Surf Eng 38(6):571–575. https://doi.org/10.1080/02670844.2022.2131043

Hsieh C-T, Wu F-L, Chen W-Y (2009) Super water- and oil-repellencies from silica-based nanocoatings. Surf Coat Technol 203(22):3377–3384. https://doi.org/10.1016/j.surfcoat.2009.04.025

Zhao O, Collinson DW, Ohshita S, Naito M, Nakano N, Tortissier G et al (2022) Insights into the mechanical properties of ultrathin perfluoropolyether–silane coatings. Langmuir 38(20):6435–6442. https://doi.org/10.1021/acs.langmuir.2c00625

Daikin (2024a) OPTOOL anti-smudge coating. https://www.daikinchemicals.com/solutions/products/optool-anti-smudge-coating.html. Accessed 20 Oct 2024

Galvez M (2020) New innovations in coating technologies for display glass. J Soc Inf Display 36(5):1–56. https://doi.org/10.1002/msid.1147

Knowde (2024a) FluoroSyl 880.00. https://www.knowde.com/stores/cytonix-llc/products/fluorosyl-880-00. Accessed 20 Oct 2024

Syensqo (2024a) Fluorolink® AD 1700. https://www.syensqo.com/en/product/fluorolink-ad-1700. Accessed 20 Oct 2024

Syensqo (2024b) Fluorolink® MD 700. https://www.syensqo.com/en/product/fluorolink-md-700. Accessed 20 Oct 2024

Knowde (2024b) OPTOOL DSX-E. https://www.knowde.com/stores/daikin/products/optool-dsx-e. Accessed 20 Oct 2024

Knowde (2024c) OPTOOL UD120. https://www.knowde.com/stores/daikin/products/optool-ud120. Accessed 20 Oct 2024

Knowde (2024d) OPTOOL DAC-HP. https://www.knowde.com/stores/daikin/products/optool-dac-hp. Accessed 20 Oct 2024

Firouzjaei MD, Zolghadr E, Ahmadalipour S, Taghvaei N, Akbari Afkhami F, Nejati S et al (2022) Chemistry, abundance, detection and treatment of per- and polyfluoroalkyl substances in water: a review. Environ Chem Lett 20:661–679. https://doi.org/10.1007/s10311-021-01340-6

Le V-G, Nguyen M-K, Nguyen H-L, Thai V-A, Le V-R, Vu QM et al (2024) Ecotoxicological response of algae to contaminants in aquatic environments: a review. Environ Chem Lett 22:919–939. https://doi.org/10.1007/s10311-023-01680-5

Nannaware M, Mayilswamy N, Kandasubramanian B (2024) PFAS: exploration of neurotoxicity and environmental impact. Environ Sci Pollut Res 31:12815–12831. https://doi.org/10.1007/s11356-024-32082-x

Pesonen M, Vähäkangas K (2024) Involvement of per- and polyfluoroalkyl compounds in tumor development. Arch Toxicol 98:1241–1252. https://doi.org/10.1007/s00204-024-03685-7

Lohmann R, Cousins IT, DeWitt JC, Glüge J, Goldenman G, Herzke D et al (2020) Are fluoropolymers really of low concern for human and environmental health and separate from other PFAS? Environ Sci Technol 54(20):12820–12828. https://doi.org/10.1021/acs.est.0c03244

Adi MA, Altarawneh M (2023) Formation of perfluorocarboxylic acids (PFCAs) from thermolysis of Teflon model compound. Environ Sci Pollut Res 30:21360–21367. https://doi.org/10.1007/s11356-022-23714-1

Ellis DA, Mabury SA, Martin JW, Muir DCG (2001) Thermolysis of fluoropolymers as a potential source of halogenated organic acids in the environment. Nature 412:321–324. https://doi.org/10.1038/35085548

Keating MY, Howell JL (2011) Decomposition of perfluoropolyether lubricants. J Therm Anal Calorim 106:213–220. https://doi.org/10.1007/s10973-011-1529-2

Daikin (2024b) The technical data sheet of OPTOOL DSX. https://daikin-america.com/wp-content/uploads/2023/05/TDS-OPT-001-Rev.-2-Optool-DSX-Website.pdf. Accessed 20 Oct 2024

Daikin (2024c) The technical data sheet of OPTOOL UD120. https://daikin-america.com/wp-content/uploads/2024/03/TDS-OPT-006-Rev.-4-Optool-UD120.pdf. Accessed 20 Oct 2024

Daikin (2024d) The technical data sheet of DAC-HP. https://daikin-america.com/wp-content/uploads/2023/05/TDS-OPT-005-Rev.-2-Optool-DAC-HP-Website.pdf. Accessed 20 Oct 2024

Knowde (2024e) FluoroSyl 3750Y. https://www.knowde.com/stores/cytonix-llc/products/fluorosyl-3750y. Accessed 20 Oct 2024

Cytonix (2024) CytoSyl 3750, 3750Y, and 2500Y technical data sheets. https://cdn.shopify.com/s/files/1/0399/3842/4987/files/TDS_3750_3750Y_and_2500Y_compare.pdf. Accessed 20 Oct 2024

AGC (2024) Asahiklin AE3000. https://www.fastma.com.cn/Upload/Images/file/20230414/6381706834943351861990784.pdf. Accessed 20 Oct 2024

3M (2024a) 3M™ Novec™ 2202 electronic coating agent. https://multimedia.3m.com.cn/mws/media/939893O/3m-novec-2202-electronic-grade-coating.pdf. Accessed 20 Oct 2024

3M (2024b) 3M™ Novec™ 7200DL engineered fluid. https://multimedia.3m.com.cn/mws/media/73723O/3mtm-novectm-7200dl-engineered-fluid.pdf. Accessed 20 Oct 2024

3M (2024c) 3M™ Novec™ 1720 electronic coating agent. https://multimedia.3m.com.cn/mws/media/234297O/3m-novec-1720-electronic-grade-coating.pdf. Accessed 20 Oct 2024

3M (2024d) 3M™ Novec™ 7100DL engineered fluid. https://multimedia.3m.com.cn/mws/media/104167O/3mtm-novectm-7100dl-engineered-fluid.pdf. Accessed 20 Oct 2024

Khadanga V, Mishra PC (2024) A review on toxicity mechanism and risk factors of nanoparticles in respiratory tract. Toxicology 504:153781. https://doi.org/10.1016/j.tox.2024.153781

Ale A, Gutierrez MF, Rossi AS, Bacchetta C, Desimone MF, Gazenave J (2021) Ecotoxicity of silica nanoparticles in aquatic organisms: an updated review. Environ Toxicol Pharmacol 87:103689. https://doi.org/10.1016/j.etap.2021.103689

Book F, Ekvall MT, Persson M, Lönnerud S, Lammel T, Sturve J (2019) Ecotoxicity screening of seven different types of commercial silica nanoparticles using cellular and organismic assays: importance of surface and size. NanoImpact 13:100–111. https://doi.org/10.1016/j.impact.2019.01.001

Mohammadi P, Abbasinia M, Assari MJ, Oliaei M (2018) The toxicology of silica nanoparticles: a review. Toxicol Environ Chem 100(3):285–316. https://doi.org/10.1080/02772248.2018.1485921

Almanaa TN, Aref M, Kakakhel MA, Elshopakey GE, Mahboub HH, Abdelazim AM et al (2022) Silica nanoparticle acute toxicity on male rattus norvegicus domestica: ethological behavior, hematological disorders, biochemical analyses, hepato-renal function, and antioxidant-immune response. Front Bioeng Biotechnol 10:868111. https://doi.org/10.3389/fbioe.2022.868111

Rashidian G, Mohammadi-Aloucheh R, Hosseinzadeh-Otaghvari F, Chupani L, Stejskal V, Samadikhah H et al (2023) Long-term exposure to small-sized silica nanoparticles (SiO2-NPs) induces oxidative stress and impairs reproductive performance in adult zebrafish (danio rerio). Comp Biochem Phys C 273:109715. https://doi.org/10.1016/j.cbpc.2023.109715

ProofTech (2024a) ProofTech Liquid Glass Screen Protector for all smartphones tablets and watches–bottle. https://getprooftech.com/product/prooftech-liquid-glass-screen-protector-for-all-smartphones-tablets-and-watches-bottle/. Accessed 20 Oct 2024

ProofTech (2024b) Liquid Ceramic Screen Protector with $300 guarantee for all phones tablets and smart watches. https://getprooftech.com/product/liquid-ceramic-glass-screen-protector-with-300. Accessed 20 Oct 2024

ProofTech (2024c) OLEOPEL Oleophobic Coating Kit for all smartphones tablets smart watches and touch screens–bottle. https://getprooftech.com/product/oleopel-oleophobic-coating-wipe-on-kit. Accessed 20 Oct 2024

CCM GmbH (CCM) (2024) Mobile Phone Coatings. https://www.ccm-liquid-glass.com/en/products/liquid-glass/nano-scale-coatings/mobile-phone-coatings/. Accessed 20 Oct 2024

Amazon (2024a) Liquid Glass Screen Protector—wipe on scratch and shatter resistant nano protection for all phones tablets smart watches universal. https://www.amazon.com/-/zh/dp/B0BTZYM75V. Accessed 20 Oct 2024

Amazon (2024b) ClearView Liquid Glass Screen Protector|covers up to 6 devices|for all smartphones tablets and watches. https://www.amazon.com/ClearView-Protector-Smartphones-Tablets-Watches/dp/B08K8DJLG4. Accessed 20 Oct 2024

Target (2024) ClearView Liquid Glass Screen Protector for all smartphones tablets and watches–3 pack. https://www.target.com/p/clearview-liquid-glass-screen-protector-for-all-smartphones-tablets-and-watches-3-pack/-/A-90602188. Accessed 20 Oct 2024

Kateliev P (2015) Oleophobic coating—what it is, how to clean your phone, what to do if the coating wears off. https://www.phonearena.com/news/Oleophobic-coating--what-it-is-how-to-clean-your-phone-what-to-do-if-the-coating-wears-off_id65974. Accessed 20 Oct 2024

Min K, Han J, Park B, Cho E (2018) Characterization of mechanical degradation in perfluoropolyether film for its application to antifingerprint coatings. ACS Appl Mater Interfaces 10(43):37498–37506. https://doi.org/10.1021/acsami.8b13159

Lotfi R, van Duin ACT, Biswas MM (2018) Molecular dynamics simulations of perfluoropolyether lubricant degradation in the presence of oxygen, water, and oxide nanoparticles using a reaxff reactive force field. J Phys Chem C 122(5):2684–2695. https://doi.org/10.1021/acs.jpcc.7b09660

Wang X, Shen J (2012) A review of contamination-resistant antireflective sol–gel coatings. J Sol-Gel Sci Technol 61:206–212. https://doi.org/10.1007/s10971-011-2615-4

Lee J, Chun S-W, Kang H-J, Talke FE (2007) The effect of UV stabilizer on the photo degradation of perfluoropolyether lubricants used in hard disk. Tribol Lett 28:117–121. https://doi.org/10.1007/s11249-007-9255-4

Su Y, Wang X, Zhao H, Zhang C, Yuan F, Guo J et al (2023) UV resistance of sol–gel hydrophobic silica antireflective coatings. J Sol-Gel Sci Technol 106:381–392. https://doi.org/10.1007/s10971-022-05729-9

Brookes T (2020) How to protect and restore your smartphone's oleophobic coating. https://www.howtogeek.com/662731/how-to-protect-and-restore-your-smartphones-oleophobic-coating. Accessed 20 Oct 2024

Anderer J (2022) ‘Zombie eating’: 88% of adults dine while staring at a screen, survey finds. https://studyfinds.org/zombie-eating-88-percent-adults-dine-while-staring-at-screen-survey-finds/. Accessed 20 Oct 2024

Li Q, Yuan M, Shangguan J, Guo M, Wu J, Zhang Y et al (2021) Insights into persistent toxic substances in protective cases of mobile phones: occurrence, health risks, and implications. Environ Sci Technol 55(9):6076–6086. https://doi.org/10.1021/acs.est.0c07603

Yu L, Ru S, Zheng X, Chen S, Guo H, Gao G et al (2021) Brominated and phosphate flame retardants from interior and surface dust of personal computers: insights into sources for human dermal exposure. Environ Sci Pollut Res 28:12566–12575. https://doi.org/10.1007/s11356-020-11132-0

Bishara SE, Warren JJ, Broffitt B, Levy SM (2006) Changes in the prevalence of nonnutritive sucking patterns in the first 8 years of life. Am J Orthod Dentofac Orthop 130(1):31–36. https://doi.org/10.1016/j.ajodo.2004.11.033

Kelly JE, Sanchez M, Van Kirk LE (1973) An assessment of the occlusion of the teeth of children 6–11 years. Vital Health Stat 11(130):1–60

KidsHealth (2024) Your child's habits. https://kidshealth.org/en/parents/five-habits.html. Accessed 20 Oct 2024

Ma Z, Peng J, Zhu Z, Chen M, Cai M, Zuo J et al (2019) Characteristic analysis of organic fluorosis caused by applying of touch screen anti-fingerprint nanocoating material. Chin J Ind Hyg Occup Dis 37(12):921–925

Bankmycell (2024) How many smartphones are in the world? (2024). https://www.bankmycell.com/blog/how-many-phones-are-in-the-world. Accessed 20 Oct 2024

Common sense media (CSM) (2019) The common sense census: media use by tweens and teens, 2019. https://www.commonsensemedia.org/sites/default/files/research/report/2019-census-8-to-18-full-report-updated.pdf. Accessed 20 Oct 2024

Trott M, Driscoll R, Iraldo E, Pardhan S (2022) Changes and correlates of screen time in adults and children during the COVID-19 pandemic: a systematic review and meta-analysis. eClinicalMedicine 48:101452. https://doi.org/10.1016/j.eclinm.2022.101452

Cheng Z, Shi Q, Wang Y, Zhao L, Li X, Sun Z et al (2022) Electronic-waste-driven pollution of liquid crystal monomers: environmental occurrence and human exposure in recycling industrial parks. Environ Sci Technol 56(4):2248–2257. https://doi.org/10.1021/acs.est.1c04621

Feng J-J, Sun X-F, Zeng EY (2022) Emissions of liquid crystal monomers from obsolete smartphone screens in indoor settings: characteristics and human exposure risk. Environ Sci Technol 56(12):8053–8060. https://doi.org/10.1021/acs.est.2c01094

Zhang S, Yang M, Li Y, Wang Y, Lu Y, Cheng Z et al (2022) Occurrence, distribution, and human exposure of emerging liquid crystal monomers (LCMs) in indoor and outdoor dust: a nationwide study. Environ Int 164:107295. https://doi.org/10.1016/j.envint.2022.107295

Ateia M, Scheringer M (2024) From “forever chemicals” to fluorine-free alternatives. Science 385(6706):256–258. https://doi.org/10.1126/science.ado5019

Wen J, Su Z, Zhu F, Fan H (2023) Construction of a fluorine-free anti-smudge waterborne polyurethane coating. Prog Org Coat 174:107254. https://doi.org/10.1016/j.porgcoat.2022.107254

Khan A, Huang K, Sarwar MG, Rabnawaz M (2020) High modulus, fluorine-free self-healing anti-smudge coatings. Prog Org Coat 145:105703. https://doi.org/10.1016/j.porgcoat.2020.105703

Rabnawaz M, Liu G, Hu H (2015) Fluorine‐free anti‐smudge polyurethane coatings. Angew Chem Int Edit 54(43):12722–12727. https://doi.org/10.1002/anie.201504892

Gu R, Li X, Mi H-Y, Han J, Zhang C, Liu C et al (2024) Transparent, robust, and anti-fingerprint silicone coating with a three-dimensional cross-linked network enabled by hydrosilylation reaction. Prog Org Coat 196:108749. https://doi.org/10.1016/j.porgcoat.2024.108749

Siriviriyanun A, Imae T (2014) Anti-fingerprint properties of non-fluorinated organosiloxane self-assembled monolayer-coated glass surfaces. Chem Eng J 246:254–259. https://doi.org/10.1016/j.cej.2014.02.066

Zhong X (2020) Preparation, performance, and application of fluorine-free anti-fouling coatings. Dissertation (in Chinese), South China University of Technology. https://doi.org/10.27151/d.cnki.ghnlu.2020.000230

Liu C, Jiao S, Sun Z, Wang T, Liu Y, Meng X et al (2024) Development of a hyperbranched oxazolidinone dynamic omniphobic liquid-like coating with high hardness and flexibility. Appl Surf Sci 654:159351. https://doi.org/10.1016/j.apsusc.2024.159351

.png)