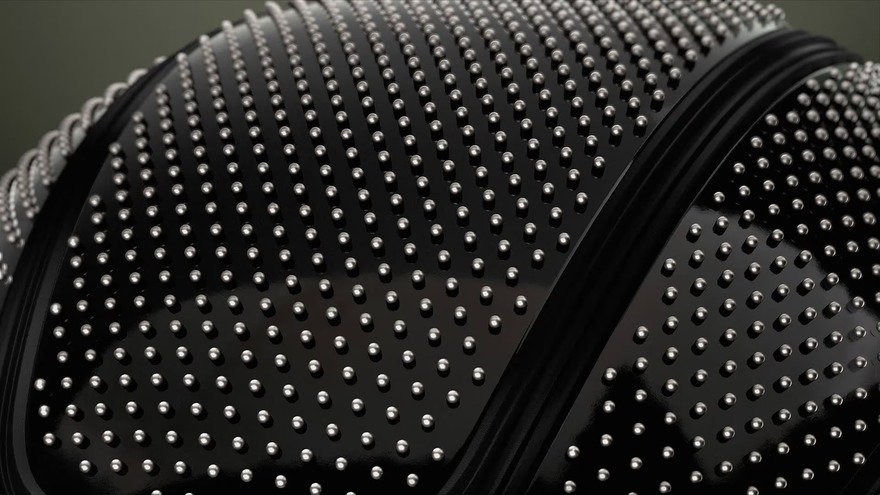

Jamie Cook's ball-bearing-based Release Layer System

Bicycle helmets have come a long way. Research shows that mere plastic shells and bits of foam aren't cutting it; in bike crashes, major damage can occur when the rider's head is subjected to rotational forces, and manufacturers are increasingly recognizing that new design approaches are needed to counter this. As British engineer Jamie Cook, who co-founded 3D-printed bike helmet company HEXR, explains:

"Helmets have always been built to sacrifice their structure in order to protect the helmet wearer. But the conventional approach to absorb energy has always resulted in helmets that work like some kind of second skull, focusing their protection strategy on basic impacts that happen directly.

"But we now know that it's rotational forces generated by angled impacts that contribute to the stretching and shearing of brain tissue. We also know that doctors and scientists believe that this kind of damage is a primary cause of traumatic brain injury."

A company called Wavecel Technologies, which we looked at here, has developed an energy-redirecting grid inside the helmet. Here's how that works when subjected to rotational force:

Cook has developed his own approach, after a particularly compelling testing session at HEXR. "We were busy developing a cycling helmet we hoped would show promising numbers for mitigating rotational force. One day while testing new ideas in the lab, the shell completely disconnected upon impact:"

"Because this kind of thing happens all the time when moving fast and testing rough samples, we didn't think anything of it. But when we saw the test results, we were floored."

The very act of the shell disconnecting, it turns out, meant that the shell took a bunch of energy with it. Inspired, Cook devised the Release Layer System (RLS). With this design, the inner portion of the helmet is covered in ball bearings.

1. Patented Release Panels

2. Fastened to a Bearing Layer

3. Bonded to the helmet shell

This arrangement allows the outer panels to shear in an impact. Adding that capability makes a massive difference, as you can see below:

The "angled-anvil" drop test shown [above] is the standard way to measure how well a helmet can dissipate rotational force. [Watching it,] you can see how a conventional helmet spins because of the rotational forces that have been created by the angled impact. In comparison, the same helmet with RLS spins much less because of the technology's remarkable ability to redirect the dangerous rotational energy away from the wearer's brain.

After years of testing and development, RLS is ready for prime time. Cook spun RLS off as its own company, which he now runs, and the system made its debut this month with HEXR's $150 Miden RLS helmet. Manufacturer Canyon will also reportedly be incorporating RLS in their forthcoming Deflectr Trail Helmet, though no launch date had been announced at press time.

.png)