- Article

- Open access

- Published: 16 July 2025

- Shunsuke Sato1,

- Hirobumi Tobe2,

- Kenichiro Sawada3,

- Chihiro Tokoku ORCID: orcid.org/0000-0003-0462-87974,

- Takao Nakagawa3,5,

- Eiichi Sato3,

- Yoshikazu Araki ORCID: orcid.org/0000-0001-9569-17536,

- Sheng Xu ORCID: orcid.org/0000-0002-5299-66421,7,

- Xiao Xu ORCID: orcid.org/0000-0003-4301-28481,

- Toshihiro Omori ORCID: orcid.org/0000-0001-9174-02391 &

- …

- Ryosuke Kainuma ORCID: orcid.org/0000-0003-0713-61061

Communications Engineering volume 4, Article number: 124 (2025) Cite this article

-

1373 Accesses

-

50 Altmetric

Abstract

Actuators are widely used in various mechanical products. However, there have been no actuators that can exhibit high actuation stresses and strains at cryogenic temperatures. Although shape memory alloys (SMAs) are attractive candidates for thermally driven actuators with high actuation stresses and strains, the operation of conventional SMAs is limited to a narrow temperature range near the room temperature. Here, we report the shape memory effect under tensile conditions with a high work output across a wide temperature range of 50–270 K in Cu-Al-Mn-based alloys. In addition, a mechanical heat switch using Cu-Al-Mn was designed for thermal insulation in space infrared telescope, and we demonstrated the operation at around 100 K. These results indicate that Cu-Al-Mn SMAs are potential cryogenic actuators with high actuation stress and strain that would contribute to the development of low temperature technologies in various fields including space astronomy, superconductivity, and liquefied gas industry.

Similar content being viewed by others

Introduction

Actuators provide physical movements with force by converting physical, chemical, electrical, or magnetic energy. These are utilized in many fields as device-control mechanisms. Although solenoidal, hydraulic, and pneumatic actuators have conventionally been used, shape-changing materials such as piezoelectric materials, magnetostrictive materials, and shape memory alloys (SMAs) have received considerable attention as actuator materials. This is because of their advantages of miniaturization and multifunctionality compared with conventional actuators. Among these, SMAs can generate large recovery stresses and strains. This results in energy densities higher than those of other materials. Thus, these have yielded substantial opportunities for robust and lightweight elements in various applications1.

SMAs are attractive materials that exhibit the shape memory effect (SME) and superelasticity (SE) caused by the reversible diffusionless transformation between the parent phase (high-temperature phase) and martensite phase (low-temperature phase)2,3. The SME is a phenomenon in which a deformed SMA recovers its original shape when heated to a temperature above the reverse martensitic transformation temperature. SE exhibits a large amount of recoverable strain by unloading a deformed SMA, which is associated with a reversible stress-induced martensitic transformation. The SME is used in applications such as thermal actuators.

Many types of SMAs have been identified, such as Ti-Ni alloys, Cu-based alloys, and Fe-based alloys4. Among these, Ti-Ni-based alloys are the most widely used in practical applications. However, Ti-Ni alloys can exhibit the superior properties only in a limited temperature range (approximately 250–370 K) because of limitations in the martensitic transformation temperatures5,6. However, applications in various industries such as the aerospace, automotive, and liquefied gas industries require higher or lower operating temperatures, e.g., 100–400 K for space, 200–400 K for automobile/aircraft, and 0–100 K for liquid He/H2/N2 storage. Therefore, SMAs that operate at high or low temperatures are desirable for actuators or sensors. Considerable efforts have been undertaken to develop high-temperature SMAs7,8,9,10,11. However, investigations of shape memory properties at cryogenic temperatures are relatively few not withstanding the fact that low-temperature technologies have recently received increased attention, e.g., because of the increased demand for the delivery and storage of liquid hydrogen for the global mission of carbon neutrality. Low-temperature technologies are crucial for space science and exploration. In lunar and deep-space exploration, it is important to effectively control the temperature of various pieces of equipment on spacecraft and rovers. In addition, astronomical observation satellites are equipped with cooling systems for observation instruments and detectors to reduce noise for high-sensitivity observations. This requires highly reliable temperature control technology12. Piezoelectric materials feature high displacement accuracy and high response speed, and there have been reports on piezoelectric materials for cryogenic applications, including PMN-PT that can exhibit displacement close to room temperature even at 77 K13,14,15,16,17,18,19. Magnetostrictive materials are also candidates for cryogenic actuators, and magnetostriction at low temperatures has been reported in some alloys, including TbDy alloys20,21,22,23,24, FeGa alloy25, and LaFeAl alloy26. Despite the efforts of many researchers, widespread practical applications of these materials at cryogenic temperatures are still challenging, presumably due to insufficient displacement induced by external fields14,16. In addition, the high work output of SMAs is also attractive for cryogenic applications.

It has been reported that the stress hysteresis in Ni-rich Ti-Ni and Ti-Ni-Cu alloys increases dramatically with a decrease in temperature below 120–150 K6,27,28. More importantly, the entropy difference between the parent and martensite phases generally becomes considerably smaller at lower temperatures and attains zero at 0 K. These imply that thermal martensitic transformation is unlikely and that an efficient work output is unlikely at cryogenic temperatures. Attempts have been undertaken to obtain low martensitic transformation temperatures in Ti-Ni-based alloys. However, this has achieved limited success29.

Cu-based SMAs such as Cu-Al-Ni and Cu-Zn-Al have been investigated extensively30,31,32,33,34. The transformation temperatures decrease with an increase in the Al content in Cu-Al-Ni alloys30. Moreover, SE at 77 K was demonstrated by Nikolaev et al.35. However, these conventional Cu-based SMAs are too brittle to be sufficiently cold-worked36. In contrast, Cu-Al-Mn alloys with a low Al content of approximately 17 at.% display a remarkable cold workability37,38,39. Under low-temperature SME, an increase in stress during heating from 77 K to 293 K under a fixed strain in a Cu-Al-Mn alloy deformed at 77 K was demonstrated by Zak et al.40. Recently, Niitsu et al. reported that Cu-Al-Mn alloys exhibit SE at cryogenic temperatures up to 4.2 K with a small stress hysteresis, unlike Ti-Ni alloys41. Although recently reported at temperatures of at least approximately 180 K in Cu-Al-Mn alloys42,43,44, strain recovery induced by temperature variation (i.e., SME) has not been achieved at cryogenic temperatures below 180 K.

Here, we evaluate the martensitic transformation behavior in the cryogenic temperature region in the Cu-Al-Mn alloys. We report that single crystalline samples display a remarkable SME at low temperatures (≥75 K) with a high work output of approximately 107 J・m-3, by tensile isobaric cooling–heating tests that can evaluate the transformation temperatures under stress, magnitude of transformation strain, and work output.

Results

Martensitic transformation and shape memory effect

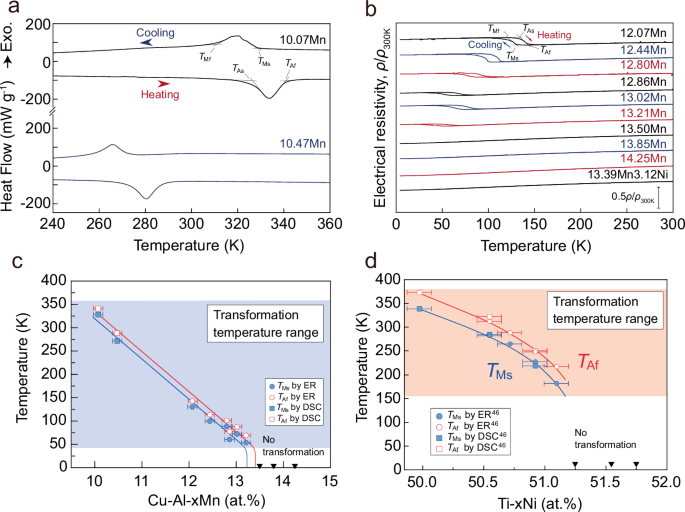

The martensitic transformation temperatures in Cu-Al-Mn alloys decrease with an increase in the Al and Mn contents, but Mn substitution of Cu lowers the transformation temperatures the most in the composition range near 17 at.% Al37,45. Although alloys with Mn contents of at most approximately 12 at.% have been examined, the martensitic transformation at lower temperatures was investigated in alloys with higher Mn content (≤ 14.25 at.%) in this study. Here, the martensitic transformation temperatures (i.e., the martensitic transformation start (TMs) and finish (TMf) temperatures and the reverse transformation start (TAs) and finish (TAf) temperatures) under zero stress were measured, and the obtained differential scanning calorimetry (DSC) and electrical resistivity (ER) curves are shown in Fig. 1a and b, respectively. The determined TMs and TAf values are plotted as functions of Mn content in Fig. 1c and listed in Supplementary Table 1. The transformation temperatures of the Cu-Al-Mn alloys decrease almost linearly to 50 K and then, decrease dramatically with an increase in Mn content. The maximum Mn content that exhibits thermal martensitic transformation is 13.21 at.% Mn in this study. Meanwhile, those in the Ti-Ni binary alloys decrease linearly to 250 K with an increase in Ni content (Fig. 1d46). Then, the linearity starts to deviate, and the temperature decreases abruptly to approximately 150 K with continued increase in Ni content. These results imply that the transformation temperatures can be controlled down to a cryogenic temperature of approximately 50 K in Cu-Al-Mn alloys by selecting a suitable Mn composition, whereas it is difficult to achieve thermal martensitic transformation below 150 K in Ti-Ni alloys. This indicates that Cu-Al-Mn alloys are potential low-temperature SMAs. Cu-Al-Mn alloys with 12.86Mn (CAM#1, TMs = 60.3 K) and higher Mn contents (CAM#2, CAM#3, and CAMN, no thermal transformation without stress) were selected for the SME tests.

a differential scanning calorimetry (DSC) curves for 10.07Mn and 10.47Mn specimens. b Electrical resistivity (ER) curves, normalized by ER value at 300 K, for 12.07Mn, 12.44Mn, 12.80Mn, 12.86Mn, 13.02Mn, 13.21Mn, 13.50Mn, 13.85Mn, 14.25Mn, and 13.39Mn3.12Ni specimens. The TMs, TMf, TAs, and TAf temperatures are defined. c Mn concentration dependence of the transformation temperatures of polycrystalline Cu-Al-Mn ternary alloys with (17.13–17.66)Al (at.%). The error bars correspond to ±0.1 at.% Mn. d Ni concentration dependence of the transformation temperatures in Ti-Ni binary alloys46. The error bars correspond to ±0.1 at.% Ni.

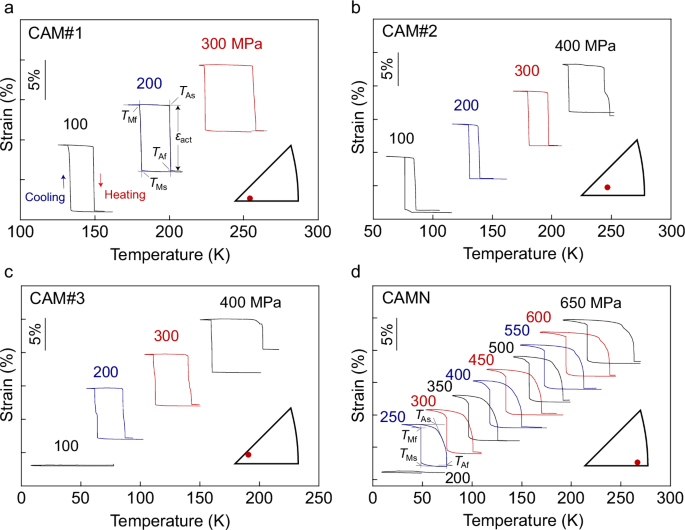

The strain–temperature (ε-T) curves obtained by the tensile isobaric cooling–heating tests on the CAM#1, CAM#2, CAM#3, and CAMN samples are shown in Fig. 2. The insets illustrate the crystallographic orientations in the tensile direction. The specimens are cooled from the parent (high-temperature) phase, and the martensitic transformation occurs at TMs under tensile stress. This results in softening owing to the transformation and an increase in the strain until the transformation is completed. When the specimens are heated from the martensite (low-temperature) phase, a reverse martensitic transformation occurs and terminates at TAf. This contributes to the recovery of the strain, i.e., SME. In most of the tests, an almost complete SME was observed. Note that the temperature intervals, TMs−TMf and TAf−TAs, are small in these single crystals under stress. Almost no response was detected in the tests under an applied stress of 100 MPa in CAM#3 and under that of 200 MPa in CAMN. This is consistent with the transformation measurements illustrating that no martensitic transformation occurred below 50 K (Fig. 1c). An irrecoverable strain was observed under an applied stress of 400 MPa in CAM#3 owing to plastic deformation. In the second test under identical conditions, the sample fractured at approximately 200 K during heating. It exhibited ductile fracture even at a low temperature of approximately 200 K, as shown on the fracture surface in Supplementary Fig. 3. The CAMN did not fracture even at 650 MPa. This is likely to have been caused by solid solution strengthening by Ni addition or the tensile direction near <110>.

a CAM#1. b CAM#2. c CAM#3. d CAMN. The inset (inverse pole figure) shows the crystallographic orientation in the tensile direction. The CAM#1, CAM#2, and CAM#3 specimens are oriented close to the <100> direction along the tensile direction. Meanwhile, CAMN is close to the <110> direction. The strain-temperature curves are shifted vertically for clarity, and scale bars are shown.

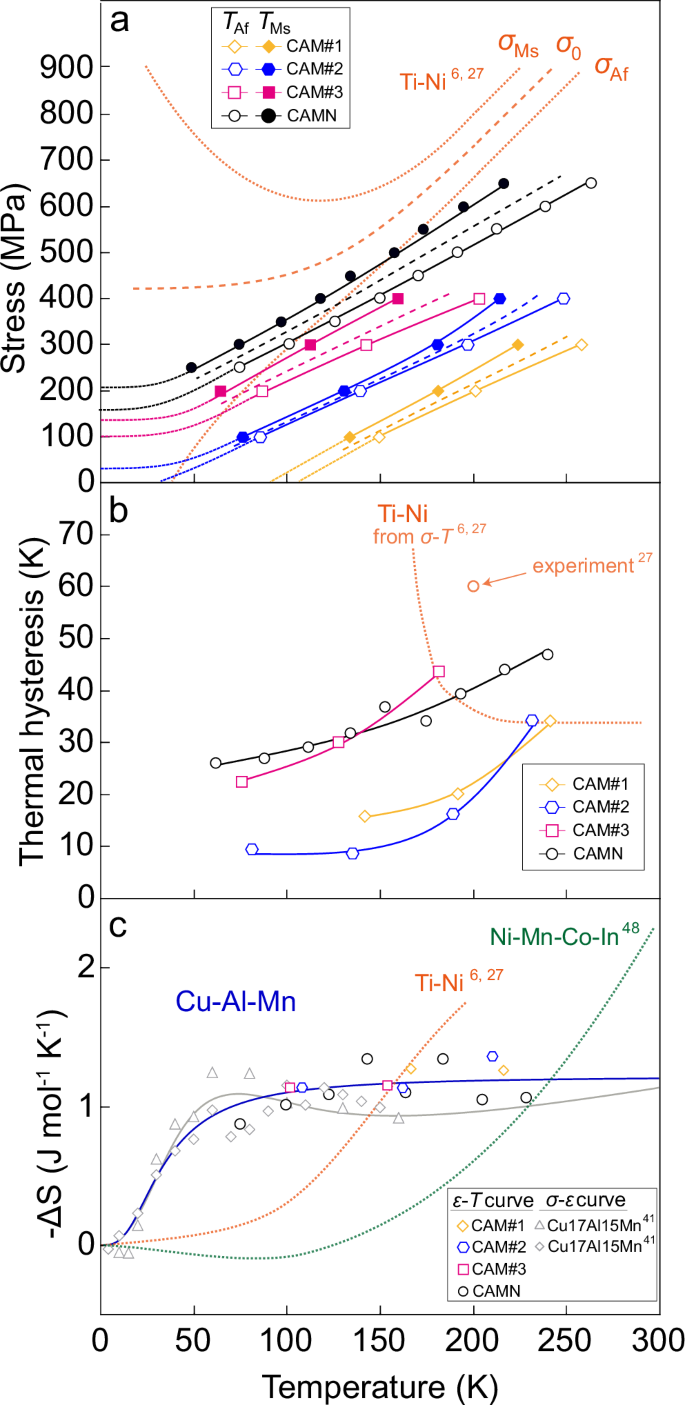

The martensitic transformation temperatures (TMs, TMf, TAs, and TAf) and actuation strain (εact) determined from the ε-T curves in Fig. 2, equilibrium temperature T0 (\(\approx\) (TAf + TMs) / 2), temperature hysteresis Thys (=TAf − TMs), and work output W (= applied stress × εact) in all the tests with various external stresses are listed in Supplementary Table 2. TMs, TAf, and Thys are plotted against those of Ti-Ni6,27 in Fig. 3a and b, respectively. As shown in Fig. 3a, the SME under stress conditions can be observed down to 75 K (TAf in CAMN) in Cu-Al-Mn-based alloys. In contrast, Ti-Ni alloys exhibit the SME only at temperatures of approximately 150 K. These TMs and TAf lines are almost consistent with σMs and σAf (Supplementary Fig. 5a) in the SE tests at various constant temperatures (Supplementary Fig. 4).

a Transformation temperatures, TMs and TAf. Dashed lines indicate the equilibrium temperature defined as 1/2(TMs + TAf). b Thermal hysteresis Thys as a function of equilibrium temperatures. c Entropy difference between martensite and parent phase ΔS. In b, the line of Ti-Ni was extracted from the curves in a. Moreover, the plot of Ti-Ni was obtained from the experimental data of the isobaric test under an applied stress of 750 MPa6. In c, the solid gray line for Cu-Al-Mn was derived from the specific heat measurements for the parent and martensite phases41.

Thermodynamic analysis

The lowest temperature for SME can be determined by the entropy difference between the parent and martensite phases, ΔS. The relationship between stress and temperature for the transformation is expressed by the Clausius–Clapeyron relationship:

$$\frac{\partial \sigma }{\partial T}=-\frac{\Delta S}{{\varepsilon }_{{{{\rm{tr}}}}}\,\cdot \,{V}_{{{{\rm{m}}}}}}$$

(1)

where ΔS, εtr, and Vm are the entropy difference SM - SP, transformation strain, and molar volume, respectively. The ΔS values are calculated using the Clausius–Clapeyron relationship. Here, \(\frac{\partial \sigma }{\partial T}\) is obtained from Fig. 3a (the slope between two points), εtr is approximated by εact, and Vm = 7.6 × 10−6 m3·mol−1 47. These are plotted with those of the Cu-Al-Mn alloys in the previous studies (Ti-Ni6,27 and Ni-Co-Mn-In48) in Fig. 3c. The ΔS values obtained in this work (blue solid line) are almost coincident with the values determined from the specific heat measurements (gray solid line) in Cu-Al-Mn, although the compositions were marginally different. It should be noted that the ΔS values of Cu-Al-Mn remained almost constant from room temperature to approximately 50 K. This behavior is unusual because ΔS approaches zero at temperatures below approximately 100 K and attains zero at 0 K, in most shape memory alloys including Ti-Ni6,27,41 (the orange line in Fig. 3c). According to the Clausius–Clapeyron relationship, the stress variation Δσ obtained by the temperature variation (T1 to T2) can be expressed as

$$\Delta \sigma ={\int }_{{T}_{1}}^{{T}_{2}}\left(-\frac{\Delta S}{{\varepsilon }_{{{{\rm{tr}}}}}\,\cdot \,{V}_{{{{\rm{m}}}}}}\right){dT}$$

(2)

This equation implies Δσ = 0 when ΔS = 0. This implies that the output cannot be generated by heating. The reason why the ΔS values of Cu-Al-Mn are relatively high down to 50 K is unclear. Nonetheless, this unique property of Cu-Al-Mn contributes to the wide operation temperature range even at cryogenic temperatures.

The ΔS is also related to the composition dependence of martensitic transformation temperatures shown in Fig. 1c. As Mn concentration increases, the transformation temperatures decrease, but the thermal martensitic transformation is interrupted when Mn exceeds 13.21 at.%, corresponding to TMs \(\approx\) 50 K. This is reasonable from a thermodynamic viewpoint. The driving force for thermal-induced martensitic transformation at temperature T is expressed as

$$\Delta G={\int }_{{T}_{0}}^{T}\Delta {SdT},$$

(3)

where T0 is the equilibrium temperature. Since the ΔS decreases with decreasing temperature below 50 K, sufficient driving force cannot be obtained when the temperature decreases.

Another important factor for an SME is the transformation hysteresis. The Thys in Fig. 3b increases abruptly at approximately 200 K in practical Ti-Ni. Thus, it is difficult to induce the martensitic transformation at temperatures below 150 K by cooling or stress. In contrast, the values for Cu-Al-Mn alloys are small even at cryogenic temperatures of approximately 50 K. This difference has been discussed in terms of thermally activated and non-thermally activated terms41. Note that CAM#2 has a remarkably smaller hysteresis than the others. This may be related to its crystal orientation. It has been reported that, considering Schmid’s law, multiple variants of martensite can be induced when the loading direction is located on one of the sides of the stereo-triangle, and the transformation hysteresis becomes large49. CAM#1, CAM#3, and CAMN are similar cases.

Work output

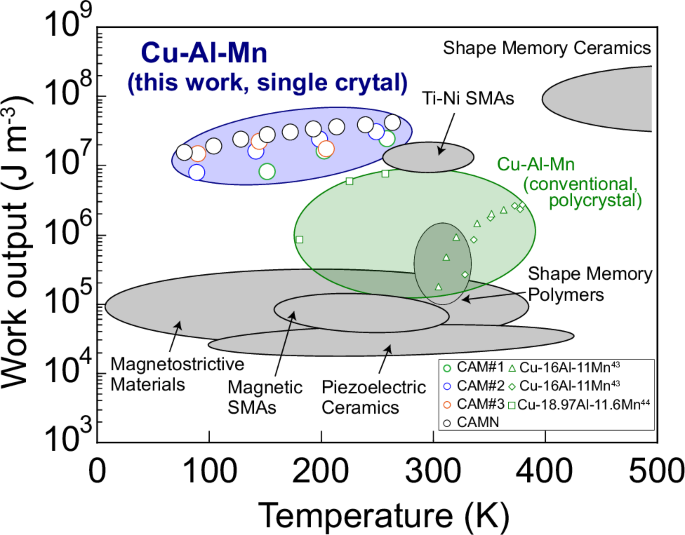

The work output (W) values of Cu-Al-Mn-based alloys are plotted in Fig. 4 as a function of TAf under different stresses. The W values in this work were higher than those of polycrystalline Cu-Al-Mn alloys in the previous studies43,44 because the values of the actuation strain of the single-crystalline specimens in this work were higher. W increased with an increase in temperature because the stress increased with the increase in temperature, as shown in Fig. 3 and Supplementary Fig. 6. The maximum W was 42.12 × 106 J·m−3 under an applied stress of 650 MP in the CAMN sample. The higher W under a higher applied stress in the CAMN alloy than in the other CAM ternary alloys was owing to the higher critical stress for slip and fracture strength, as shown in Fig. 2. Similar to other SMAs, Cu-Al-Mn-based alloys exhibit high actuation stresses and strains compared with other actuator materials including piezoelectric materials used in precision positioning devices. Meanwhile, Cu-Al-Mn alloys with single-crystalline structures can produce a high work output even at cryogenic temperatures, unlike Ti-Ni SMAs and other actuator materials (Fig. 4)1,17,18,20,24,43,44,50,51,52,53,54,55,56,57. Therefore, the present Cu-Al-Mn SMAs can be used as actuator materials that exhibit high actuation stress and strain at cryogenic temperatures and enable large actuation in low-temperature applications.

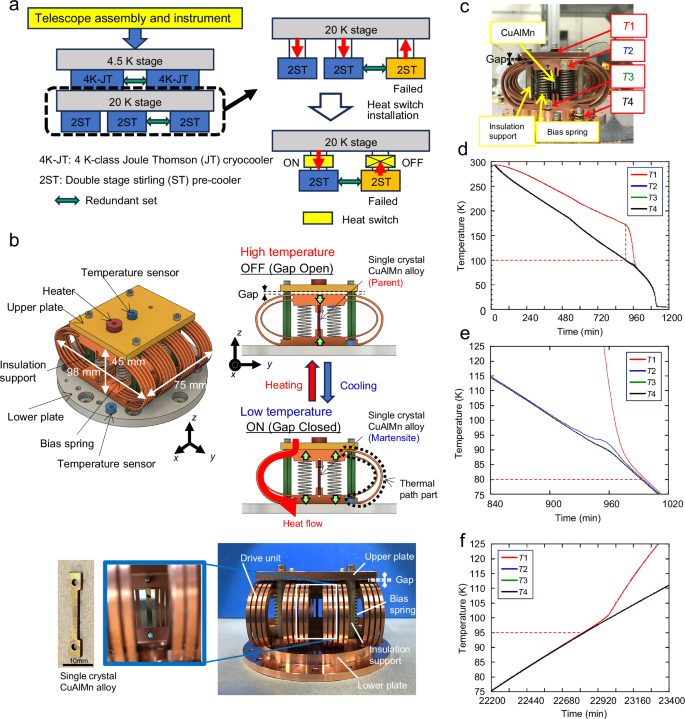

Mechanical heat switch

One of its potential applications is as a mechanical heat switch for space infrared telescopes, which are expected to reveal the evolution of galaxies and the formation of planetary systems12. To achieve high-sensitivity observations in the infrared region, it is necessary to reduce the noise caused by the thermal radiation generated by the telescope. Therefore, telescopes should be maintained at cryogenic temperatures to achieve high-sensitivity observations. Mechanical cryocoolers are generally used to cool telescopes. A redundant configuration of cryocoolers is generally adopted to ensure high reliability. For example, as shown in Fig. 5a, three mechanical cryocoolers (rather than two) are required to secure redundancy because a backup cryocooler should cool the target to compensate for the heat from the failed cryocooler58. If the SMA can disconnect a broken mechanical cryocooler from the target by functioning as a heat switch at cryogenic temperatures, the number of cryocoolers can be reduced. This results in reductions in the size, weight, and power consumption of the cooler system. However, the effectiveness of mechanical heat switches at cryogenic temperatures is limited59.

a Concept for an efficient cooling system using shape memory alloy in an infrared telescope. b A single crystal of CAM#2 is attached to a drive unit in which compressed bias springs are inserted. The heat switch turns on, and heat exchange occurs by cooling when martensitic transformation of Cu-Al-Mn occurs, and the top of the drive unit moves upward to touch the upper plate. Meanwhile, the heat switch turns off and the heat transfer is interrupted by heating when the top of the drive unit moves downward owing to the shape memory effect (SME) against the bias force, and a separation is generated between the upper plate and drive unit. c External view of heat switch using Cu-Al-Mn single crystal at room temperature, d temperature variation during cooling, e enlarged view of the switch turning on during cooling, f temperature variation during heating

To realize an effective cryogenic heat switch for operation at ≤ 150 K, we designed a heat switch using a Cu-Al-Mn single crystal at cryogenic transformation temperatures. The experimental setup of the heat switch is shown in Fig. 5b. A Cu-Al-Mn single crystal was attached to the drive unit. Tensile force was applied using four compressed bias springs. A separation of 0.35–0.40 mm existed between the upper plate and drive unit at room temperature. The drive unit was cooled by a cryocooler attached to the lower plate while heat (0.01 W) was added to the upper plate. As shown in Fig. 5d, during the first 900 min, the temperatures at T2, T3, and T4 decreased simultaneously, and the temperature at T1 was higher because of the separation. After 900 min, the trend of T1 varied. It started to approach the other temperature from approximately 100 K. This implies that the drive unit contacted the upper plate owing to martensitic transformation, and heat exchange began. The temperature of the upper plate (T1) was approximately equal to that of the drive unit (T2) at 80 K, as shown in Fig. 5e. This is known as the switch-on state. The temperature was maintained between T1 and T4 by further cooling to 5 K. Subsequently, the heat input was increased to 0.1 W, and the cooling by the cryocooler was stopped. The increase in the temperature is shown in Fig. 5f. The temperature at each point was identical. However, at approximately 95 K, the temperature of the upper plate, T1, started to be higher than those of T2, T3, and T4. It then showed a large temperature difference. This was caused by the drive unit separating from the upper part. The switch-off was accomplished using the SME.

Thus, it was demonstrated that thermal insulation can be achieved at cryogenic temperatures of approximately 100 K by heat switching using Cu-Al-Mn. This low-temperature SMA can contribute to progress in space astronomy. Moreover, Cu-Al-Mn showed good stability of thermal cycles (Supplementary Fig. 7). Because Cu-Al-Mn alloys can be driven at cryogenic temperatures with a high work output, these are potential actuator materials for cryogenic science and technology.

Methods

Specimen preparation

Cylindrical ingots of Cu-Al-Mn and Cu-Al-Mn-Ni alloys with a diameter of 20 mm were prepared using Cu (99.999%), Al (99.9%), Mn (99.9%), and Ni (99.9%) by induction melting in an Ar atmosphere. Ni was added to decrease the martensitic transformation temperatures while maintaining a high fraction of the α (FCC) phase at approximately 500 °C, which is necessary for abnormal grain growth by the cyclic heat treatment60,61,62,63. The concentrations were measured at least 7 points for each alloy using an electron probe microanalyzer (EPMA: JEOL JXA-8100) with a beam current of 8 nA and an accelerating voltage of 20 kV, where the ZAF correction method was applied using pure elements as standards. The obtained values were averaged, in which the standard deviation was 0.23 for Al and 0.13 for Mn. It was calibrated using the results of inductively coupled plasma (ICP) measurements. The nominal and measured concentrations are listed in Supplementary Table 1. The ingots were hot rolled at 1073 K and subsequently, cold rolled into sheets (Supplementary Fig. 1a). The obtained plates of four alloys (Cu-17.66Al-12.86Mn, Cu-17.24Al-13.50Mn, Cu-17.29Al-14.25Mn, and Cu-16.86Al-13.39Mn-3.12Ni (at.%); designated as CAM#1, CAM#2, CAM#3, and CAMN, respectively) were subjected to cyclic heat treatment (see Supplementary Fig. 1b) for inducing abnormal grain growth to obtain single crystals62,63. The crystallographic orientation in the rolling direction (RD) for the tensile tests was determined by electron backscattered diffraction (EBSD) attached to a field emission scanning electron microscope (FE-SEM: Philips XL-30 or JEOL JSM-7800F). Using a wire electric discharge machine, dogbone-shaped tensile samples with parallel portions of 15 × 3 × 1 mm were cut from the plates with their length direction along the RD. The specimens were annealed at 473 K for 15 min to stabilize the martensitic transformation temperatures. All the alloys were cut from the hot-rolled sheet to measure the martensitic transformation temperatures; the polycrystalline samples were solution heat-treated at 1173 K for 15 min. This was followed by ice-water quenching and aging at 473 K for 15 min in an oil bath.

Measurements of martensitic transformation temperature

The martensitic transformation temperatures (TMs, TMf, TAs, and TAf) were determined by differential scanning calorimetry (DSC: SII DSC220) with a cooling and heating rate of 10 K・min-1 at temperatures around room temperature and by the electrical resistivity (ER) measurements using the physical property measurement system (Quantum Design PPMS) with a cooling and heating rate of 2 K・min-1 at lower temperatures. The results are presented in Supplementary Table 1.

Measurements of shape memory properties

The SME was investigated by heating–cooling tests under a constant tensile stress in the range of 4–300 K (as shown in Supplementary Fig. 2) using a temperature-variable mechanical testing machine (Instron 5982). The single crystal samples were cooled to a predetermined temperature, loaded and held under constant tensile stress in the parent phase (high-temperature phase), and subjected to cooling and heating at rates of approximately 2 K·min−1 and 1 K·min−1, respectively. The strain of the sample was measured using a clip-on extensometer with high accuracy during the thermal cycle. The stress increased to the next level after each cooling–heating cycle in the parent phase. Micrographs of the fracture surfaces were obtained by FE-SEM (Philips XL-30). The SE at constant temperature was evaluated by tensile loading–unloading tests at various temperatures in the low- to high-temperature order at a strain rate of 5 × 10−5 s−1 using the same mechanical testing machine. In these tests, the strain was measured using an extensometer with a gauge length of 12.5 mm.

Test of heat switch

The Cu heat switch used in this study is shown in Fig. 5. The upper plate was held with an insulation support. A dog-bone-shaped CAM#2 single-crystal plate with <001> in the longitudinal direction (the dimensions of the center part were 2 mm × 2 mm × 14.7 mm) was attached to the drive unit. Four compressed bias springs (stainless steel, free length: 40 mm, spring constant: 6.78 N/mm at room temperature) were inserted such that a tension of approximately 100 MPa (or higher at lower temperatures) was applied to the CAM. A separation existed between the plate and the top of the drive unit. It was set at 0.35–0.4 mm at room temperature. When the drive unit is cooled by a cryocooler attached to the lower plate, the top of the drive unit moves upward and touches the upper plate (i.e., the switch is on) because of the forward martensitic transformation of the CAM subjected to a tensile force from the springs. Then, the temperature of the upper plate should be lowered. In contrast, when the temperature of the lower plate increases, the CAM contracts owing to the SME, and the drive unit moves downward. This generates a separation between the upper plate and drive unit. The upper plate was disconnected by switching it off, and heat transfer was obstructed. The temperatures of the upper and lower plates and those of the upper and lower parts of the unit drive were measured during the heating and cooling.

Data availability

The data that support the findings of this study are available on request from the corresponding authors.

References

Lagoudas, D. C. In Shape memory alloys: modeling and engineering applications. (Springer, 2008).

Otsuka, K. & Wayman, C. M. In Shape Memory Materials (eds K. Otsuka & C. M. Wayman) 27–48 (Cambridge University Press, 1999).

Chowdhury, P. & Sehitoglu, H. Deformation physics of shape memory alloys – Fundamentals at atomistic frontier. Prog. Mater. Sci. 88, 49–88 (2017).

Gangil, N., Siddiquee, A. N. & Maheshwari, S. Towards applications, processing and advancements in shape memory alloy and its composites. J. Manuf. Process. 59, 205–222 (2020).

Omori, T. et al. Superelastic effect in polycrystalline ferrous alloys. Science 333, 68–71 (2011).

Niitsu, K., Kimura, Y. & Kainuma, R. Transformation entropy change and precursor phenomena in Ni-rich Ti-Ni shape memory alloys. J. Mater. Res. 32, 3822–3830 (2017).

Ma, J., Karaman, I. & Noebe, R. D. High temperature shape memory alloys. Int. Mater. Rev. 55, 257–315 (2010).

Acar, E., Karaca, H. E., Tobe, H., Noebe, R. D. & Chumlyakov, Y. I. Characterization of the shape memory properties of a Ni45.3Ti39.7Hf10Pd5 alloy. J. Alloy. Compd. 578, 297–302 (2013).

Lee, J. I. et al. A strategy of designing high-entropy alloys with high-temperature shape memory effect. Sci. Rep. 9, 1–10 (2019).

Canadinc, D. et al. Ultra-high temperature multi-component shape memory alloys. Scr. Mater. 158, 83–87 (2019).

Li, Y., Xin, Y., Chai, L., Ma, Y. & Xu, H. Microstructures and shape memory characteristics of dual-phase Co-Ni-Ga high-temperature shape memory alloys. Acta Mater. 58, 3655–3663 (2010).

Nakagawa, T. Observations of the Universe in the Terahertz Range: From AKARI to SPICA. IEEE Trans. Terahertz Sci. Technol. 5, 1133–1139 (2015).

Xu, T.-B., Tolliver, L., Jiang, X. & Su, J. A single crystal lead magnesium niobate-lead titanate multilayer-stacked cryogenic flextensional actuator. Appl. Phys. Lett. 102 https://doi.org/10.1063/1.4790142 (2013).

Xu, T.-B. & Huffine, J. in AIAA SCITECH 2022 Forum (2022).

Xu, T.-B., Huffine, J., Jiang, X. & Zhang, S. in AIAA SCITECH 2024 Forum (2024).

Naderi, A. et al. Recent development in piezoelectric materials and devices for cryogenic environments. Sensors and Actuators A: Phys. 386 https://doi.org/10.1016/j.sna.2025.116317 (2025).

Zhang, X. L., Chen, Z. X., Cross, L. E. & Schulze, W. A. Dielectric and piezoelectric properties of modified lead titanate zirconate ceramics from 4.2 to 300 K. J. Mater. Sci. 18, 968–972 (1983).

Paik, D. S., Park, S. E., Shrout, T. R. & Hackenberger, W. Dielectric and piezoelectric properties of perovskite materials at cryogenic temperatures. J. Mater. Sci. 34, 469–473 (1999).

Thiercelin, M., Dammak, H. & Thi, M. P. in 2010 IEEE International Symposium on the Applications of Ferroelectrics (ISAF). 1-4.

Dooley, J. A. Cryogenic Magnetostrictive Actuators-Material and Applications. in Conference Proceedings for Actuator ‘98 Bremen, Germany (1998).

Dooley, J. A. et al. Magnetostriction of single crystal and polycrystalline Tb0.60Dy0.40 at cryogenic temperatures. J. Appl. Phys. 85, 6256–6258 (1999).

Dooley, J., Good, N., Graetz, J., Chave, R. & Fultz, B. in Advances in Cryogenic Engineering Materials: Volume 46, Part A (eds U. Balu Balachandran, K. Ted Hartwig, Donald U. G, & Victoria A. B) 383-389 (Springer US, 2000).

Claeyssen, F. & Lhermet, N. In 8th International Conference on New Actuators. 148–153 (2002).

Ma, T., Jiang, C. & Xu, H. Magnetostriction in 〈110〉 and 〈112〉 oriented crystals Tb0.36 Dy0.64 (Fe0.85 Co0.15) 2. Appl Phys. Lett. 86, 1–3 (2005).

Fitchorov, T. I. et al. Thermally driven large magnetoresistance and magnetostriction in multifunctional magnetic FeGa–Tb alloys. Acta Mater. 73, 19–26 (2014).

Zhao, Y. et al. Giant isotropic magnetostriction in NaZn13-type LaFe13−xAlx compounds. Appl. Phys. Lett. 110 https://doi.org/10.1063/1.4973476 (2017).

Niitsu, K., Omori, T. & Kainuma, R. Stress-induced transformation behaviors at low temperatures in Ti-51.8Ni (at. %) shape memory alloy. Appl Phys. Lett. 102, 231915 (2013).

Kimura, Y., Xu, X., Niitsu, K., Omori, T. & Kainuma, R. Martensitic transformations and superelastic behavior at low temperatures in Ti50-xNi40+xCu10 shape memory alloys. Mater. Trans. 57, 269–277 (2016).

Umale, T., Salas, D., Tomes, B., Arroyave, R. & Karaman, I. The effects of wide range of compositional changes on the martensitic transformation characteristics of NiTiHf shape memory alloys. Scr. Mater. 161, 78–83 (2019).

Recarte, V., Pérez-Sáez, R. B., San Juan, J., Bocanegra, E. H. & Nó, M. L. Influence of Al and Ni concentration on the Martensitic transformation in Cu-Al-Ni shape-memory alloys. Metall. Mater. Trans. A 33, 2581–2591 (2002).

Bonnot, E., Romero, R., Manosa, L., Vives, E. & Planes, A. Elastocaloric effect associated with the martensitic transition in shape-memory alloys. Phys. Rev. Lett. 100 https://doi.org/10.1103/PhysRevLett.100.125901 (2008).

Juan, J. S., Nó, M. L. & Schuh, C. A. Nanoscale shape-memory alloys for ultrahigh mechanical damping. Nat. Nanotechnol. 4, 415–419 (2009).

Ueland, S. M. & Schuh, C. A. Superelasticity and fatigue in oligocrystalline shape memory alloy microwires. Acta Mater. 60, 282–292 (2012).

De Castro Bubani, F., Sade, M. & Lovey, F. Large pseudoelastic strain in double β-18R–6R martensitic transformation with reduced 6R martensite stabilization in CuZAl alloys. Mater. Sci. Eng.: A 855 https://doi.org/10.1016/j.msea.2022.143909 (2022).

Nikolaev, V. I., Pul’Nev, S. A., Malygin, G. A., Shpeizman, V. V. & Nikanorov, S. P. Pseudoelastic deformation and generation of reactive stresses in a Cu-Al-Ni shape-memory alloy in the temperature range 4.2-293 K. Phys. Solid State 49, 1878–1883 (2007).

Sutou, Y., Omori, T., Kainuma, R. & Ishida, K. Ductile Cu–Al–Mn based shape memory alloys: general properties and applications. Mater. Sci. Technol. 24, 896–901 (2008).

Kainuma, R., Takahashi, S. & Ishida, K. Ductile shape memory alloys of the Cu-Al-Mn system. J. de. Phys. IV 5, C8-961–C968-966 (1995).

Kainuma, R., Takahashi, S. & Ishida, K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. Metall. Mater. Trans. A 27A, 2187–2195 (1996).

Sutou, Y., Omori, T., Kainuma, R. & Ishida, K. Ductile Cu-Al-Mn based shape memory alloys: General properties and applications. Mater. Sci. Technol. 24, 896–901 (2008).

Zak, G., Kneissl, A. C. & Zatulskij, G. Shape memory effect in cryogenic Cu-Al-Mn alloys. Scr. Mater. 34, 363–367 (1996).

Niitsu, K., Kimura, Y., Omori, T. & Kainuma, R. Cryogenic superelasticity with large elastocaloric effect. Npg Asia Mater. 10, e457 (2018).

Babacan, N., Atli, K. C., Turkbas, O. S., Karaman, I. & Kockar, B. The effect of dynamic aging on the cyclic stability of Cu73Al16Mn11 shape memory alloy. Mater. Sci. Eng.: A 701, 352–358 (2017).

Babacan, N., Ma, J., Turkbas, O. S., Karaman, I. & Kockar, B. The effects of cold rolling and the subsequent heat treatments on the shape memory and the superelasticity characteristics of Cu73Al16Mn11 shape memory alloy. Smart Mater. Struct. 27 https://doi.org/10.1088/1361-665X/aa9cc5 (2018).

Trehern, W. et al. Exploring thermomechanical functionality of CuAlMn as an extreme low temperature shape memory alloy. Mater. Lett., 131246 https://doi.org/10.1016/j.matlet.2021.131246 (2021).

Ii, S., Tsuchiya, K. & Koyano, T. Aging effect on martensitic transformation at cryogenic temperatures in Cu-Al-Mn alloy in Proceedings of 8th European Symposium on Martensitic Transformations (eds Šittner, P., Paidar, V., Heller, L., & Seiner, H.) 02011 (EDP Sciences, 2009).

Niitsu, K., Kimura, Y., Xu, X. & Kainuma, R. Composition dependences of entropy change and transformation temperatures in Ni-rich Ti–Ni system. Shape Mem. Superelast. 1, 124–131 (2015).

Sutou, Y., Koeda, N., Omori, T., Kainuma, R. & Ishida, K. Effects of aging on stress-induced martensitic transformation in ductile Cu–Al–Mn-based shape memory alloys. Acta Mater. 57, 5759–5770 (2009).

Niitsu, K., Xu, X., Umetsu, R. Y. & Kainuma, R. Stress-induced transformations at low temperatures in a Ni45Co5Mn36In14 metamagnetic shape memory alloy. Appl. Phys. Lett. 103, 242406 (2013).

Omori, T., Kawata, S. & Kainuma, R. Orientation dependence of superelasticity and stress hysteresis in Cu-Al-Mn alloy. Mater. Trans. 61, 55–60 (2020).

Lai, A., Du, Z., Gan, C. L. & Schuh, C. A. Shape memory and superelastic ceramics at small scales. Science 341, 1505–1508 (2013).

Grummon, D. S. Thin-film shape-memory materials for high-temperature applications. Miner. Met. Mater. Soc. 55, 24–32 (2003).

Karaca, H. E. et al. Effects of nanoprecipitation on the shape memory and material properties of an Ni-rich NiTiHf high temperature shape memory alloy. Acta Mater. 61, 7422–7431 (2013).

Liu, C., Qin, H. & Mather, P. T. Review of progress in shape-memory polymers. J. Mater. Chem. 17, 1543–1558 (2007).

Heczko, O. & Straka, L. Temperature dependence and temperature limits of magnetic shape memory effect. J. Appl. Phys. 94, 7139–7143 (2003).

Karaca, H. E., Karaman, I., Basaran, B., Chumlyakov, Y. I. & Maier, H. J. Magnetic field and stress induced martensite reorientation in NiMnGa ferromagnetic shape memory alloy single crystals. Acta Mater. 54, 233–245 (2006).

Heczko, O., Sozinov, A. & Ullakko, K. Giant field-induced reversible strain in magnetic shape memory NiMnGa alloy. IEEE Trans. Magn. 36, 3266–3268 (2000).

Suzumori, K. Expectations about new actuators. Trans. Jpn. Soc. Mech. Eng. Ser. C. 77, 2412–2419 (2011).

Ishikawa, K., Tobe, H. & Sato, E. The development of Cu-Al-Mn shape memory actuator for cryogenic environment. In 35th Symposium on Aerospace Structure and Materials (2019).

DiPirro, M. J. & Shirron, P. J. Heat switches for ADRs. Cryogenics 62, 172–176 (2014).

Sutou, Y., Kainuma, R. & Ishida, K. Effect of alloying elements on the shape memory properties of ductile Cu-Al-Mn alloys. Mater. Sci. Eng. A 273-275, 375–379 (1999).

Omori, T., Koeda, N., Sutou, Y., Kainuma, R. & Ishida, K. Superplasticity of Cu-Al-Mn-Ni shape memory alloy. Mater. Trans. 48, 2914–2918 (2007).

Omori, T. et al. Abnormal grain growth induced by cyclic heat treatment. Science 341, 1500–1502 (2013).

Kusama, T. et al. Ultra-large single crystals by abnormal grain growth. Nat. Commun. 8, 354 (2017).

Acknowledgements

This work was supported by JSPS KAKENHI (Grant numbers JP21K18179, JP23K23070, JP23H05441, and JP23K17695) and the Open Innovation Hub for Expanding Humanosphere and the Domain of Human Activity through Solar System Frontier Development, The Japan Aerospace Exploration Agency (JAXA), Japan.

Ethics declarations

Competing interests

The authors declare no competing interests.

Peer review

Peer review information

Communications Engineering thanks Tian-Bing Xu, Dilibal Savas and the other, anonymous, reviewer(s) for their contribution to the peer review of this work. Primary Handling Editors: [Miranda Vinay and Rosamund Daw].

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License, which permits any non-commercial use, sharing, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if you modified the licensed material. You do not have permission under this licence to share adapted material derived from this article or parts of it. The images or other third party material in this article are included in the article’s Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by-nc-nd/4.0/.

About this article

Cite this article

Sato, S., Tobe, H., Sawada, K. et al. Shape memory alloys for cryogenic actuators. Commun Eng 4, 124 (2025). https://doi.org/10.1038/s44172-025-00464-9

Received: 13 June 2024

Accepted: 01 July 2025

Published: 16 July 2025

DOI: https://doi.org/10.1038/s44172-025-00464-9

.png)

![How Do CPUs Work? The Engineering That Runs the Digital World [video]](https://www.youtube.com/img/desktop/supported_browsers/chrome.png)