Welcome to the first-ever weekly newsletter from Potential Surface! Each week, you’ll find bite-sized summaries of the latest research and tech innovations, along with my personal take on what it all means.

Today’s newsletter covers:

The Nobel prize winning ‘molecular sponges’ and their surprising uses in biosecurity.

A 200% safer AI-designed car bumper that may never materialise.

Virtual sensors for fusion discoveries and a tough dilemma for future science.

Chinas tariffs and the dirty secret of the rare-earth metals powering our green future.

Hope you enjoy the read :)

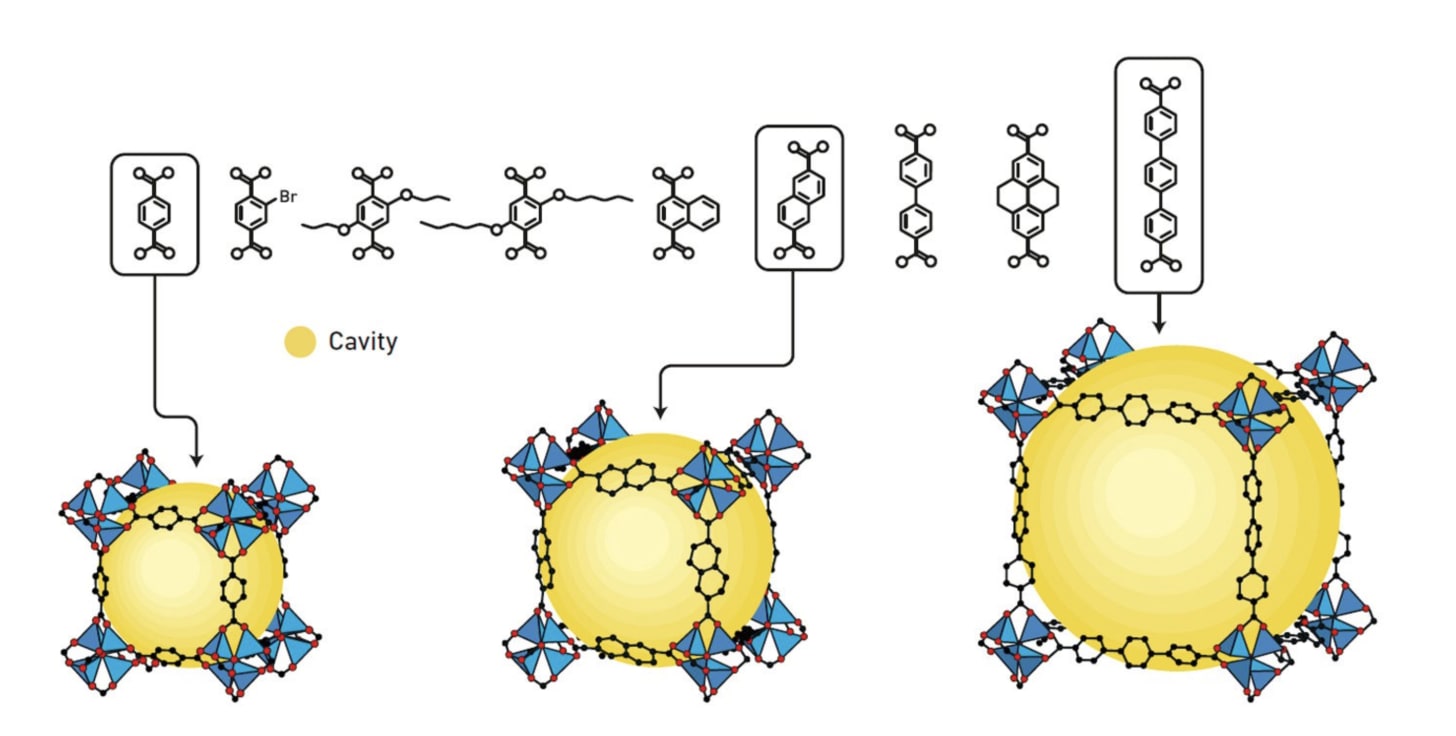

The Nobel Prizes were announced this week, and I was happy to see the development of Metal-Organic Frameworks (MOFs) getting the limelight! The name is quite self-explanatory; MOFs are crystalline materials made of metal ions linked by organic molecules, forming a highly porous framework. This three-dimensional structure has an incredibly large internal surface area, effectively making it a molecular sponge. By changing the metal or organic parts, scientists can tune these ‘sponges’ for an incredible array of applications.

There has been rapid growth in MOFs research. The most widely talked about uses are in carbon capture, gas storage, catalysis, targeted drug delivery, and harvesting water from the air.

Beyond the impressive applications you typically hear about in the press, I’m particularly excited and intrigued by the use of MOFs in biosecurity, here are some examples:

Pathogen detection: MOFs can be programmed to detect pathogens like E. coli by capturing their biomarkers, which causes the material to a visually change colour, produce an electrical signal, or the emit fluorescent light (fluorescence). Giving them potential to provide a simple and easily integratabtle detection system.

Nerve Agent Degradation: Certain zirconium-based MOFs can use their metal nodes to break down deadly nerve agents into harmless substances. This capability could allow them to be incorporated directly into protective fabrics for military personnel and first responders.

Catalyst face mask: Researchers are developing MOF-enhanced face masks that actively neutralise airborne pathogens on contact. Offering a higher level of protection than traditional masks that simply filter them. A recent paper highlighted their potential for lighter PPE, noting the masks maintain over 94% efficiency for an incredible 30 hours, far outlasting standard surgical masks.

The car bumper is a piece of engineering we see every day whose fundamental design hasn’t changed in decades.

To be crash proof, a car needs to handle everything from a gentle parking bump to a high-speed collision, and the physics of those impacts are completely different. Currently, the way we handle this is by having a squishy foam layer for the small hits, backed by a heavy metal beam for the big ones. It’s a simple solution that works, but it’s a clunky, multi-part system that adds a lot of weight.

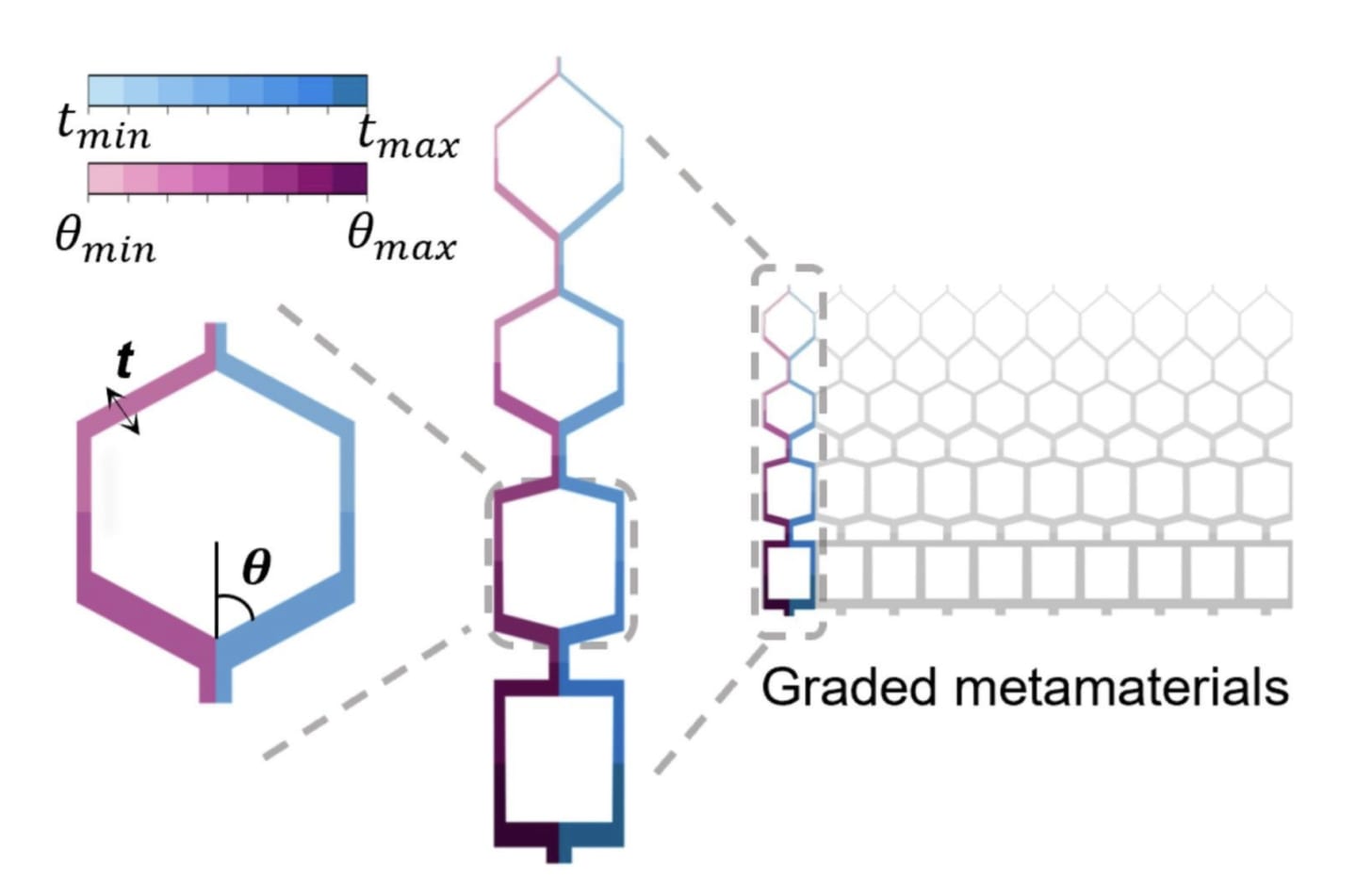

New research presented an AI-designed lightweight metamaterial that boosts impact protection by 200%. This was achieved with a tunable structure that smoothly transitions from soft to firm, allowing it to handle the different types of impact.

A metamaterial is any material that has an artificially engineered internal structure. This uniquely designed structure is what gives the metamaterials properties outside of what could be achieved by the base material alone.

The AI capability for “inverse-design” is a recent achievement of the last few years. This work on car bumpers is part of a new wave of research that aims to apply this new AI design capability to specific, real-world challenges - a trend we can expect to see a lot more of.

I’m a big fan of metamaterials (governments are too). But as exciting as these results are, I’m skeptical we’ll see cars driving around with futuristic bumpers anytime soon.

I think this for a couple reasons:

The Manufacturing Bottleneck: Right now, metamaterials are primarily made using 3D printing, which can’t come close to the massive scale and speed of the automotive industry. This touches on a wider point. For new metamaterials to live up to the applications they can now be designed for, our fabrication techniques need to catch up to our design capabilities.

Further to this, currently, the highest-resolution printers are only compatible with a very limited range of materials. So, while in theory a metamaterial can be made with any material (metals, plastics etc), actually manufacturing them can only be done for specific types of polymers.

Regulation: Outside of the metamaterial practicality issues, the validation cycle for new car safety features is notoriously long and complex. I think we’ll first need to see metamaterials becoming wide spread in other applications before we see them implemented in any type of safety feature.

If you want to go deeper into the fundamentals of metamaterials and their applications, I covered the background in an earlier post.

Scientists studying plasma in fusion reactors often face a frustrating trade-off: their fastest sensors are blurry, and their sharpest sensors are slow. A new paper details an AI model, “Diag2Diag,” that fixes this by creating high-resolution “virtual” data to fill in the gaps of the sharp but slow sensors.

The model uses a multimodal approach, meaning it was trained to synthesise information from a whole suite of different diagnostics at once (like ECE, Interferometers, and Magnetics) instead of relying on a single data stream. While the idea of using AI to fill in data isn’t new, I was still very impressed by this model’s accuracy. After training, it could reconstruct a target sensor’s complex, real-world data with an R² score of 0.92, using only information from other diagnostics and without ever seeing the target’s own live signal.

This new virtual high-resolution data was then used to support a theory about how “edge flares” (ELMs) in the plasma come about. Improving our understanding of these plasma mechanisms is critical for predicting their behaviour and designing future safe and reliable reactors.

Given the harsh environments inside fusion reactors and the struggle to obtain and analyse data AI tools like this could be extremely helpful. The paper also put forward that this method is transferable to many other fields where researchers face challenges with sparse, incomplete, or low-resolution diagnostic data.

Something that makes me feel a little unsettled is how the paper said:

[Diag2Diag] may also help to find a minimal set of diagnostics for a future reactor in which the availability of diagnostics is limited due to cost and hardware constraints.

I guess if it works then fair enough, but I wonder where the line is between the cost-effectiveness of replacing some physical hardware with “virtual” AI-generated data versus the potential risks of relying on that synthetic data for scientific discovery and operational decisions. I imagine this is a line we will soon find.

You may have seen the latest drama with rare-earth metals. The headline is that China is putting tariffs on rare-earth metals. If China goes ahead with this, it would be bad to say the least, as the bottom line is that we use rare earths for so many crucial technologies, and China supplies over 90% of the global market and 98% of EU supplies. While many people are (rightly) focusing on the impact this could have on chip manufacturing, especially in the context of the US-China AI race, my mind instantly went to the magnet industry.

I flagged this vulnerability a few years ago while researching rare-earth superconductors. By market value, 91% of rare earths go into high-performance magnets that are used in EVs, wind turbines, MRI machines, fusion reactors, to name a few.

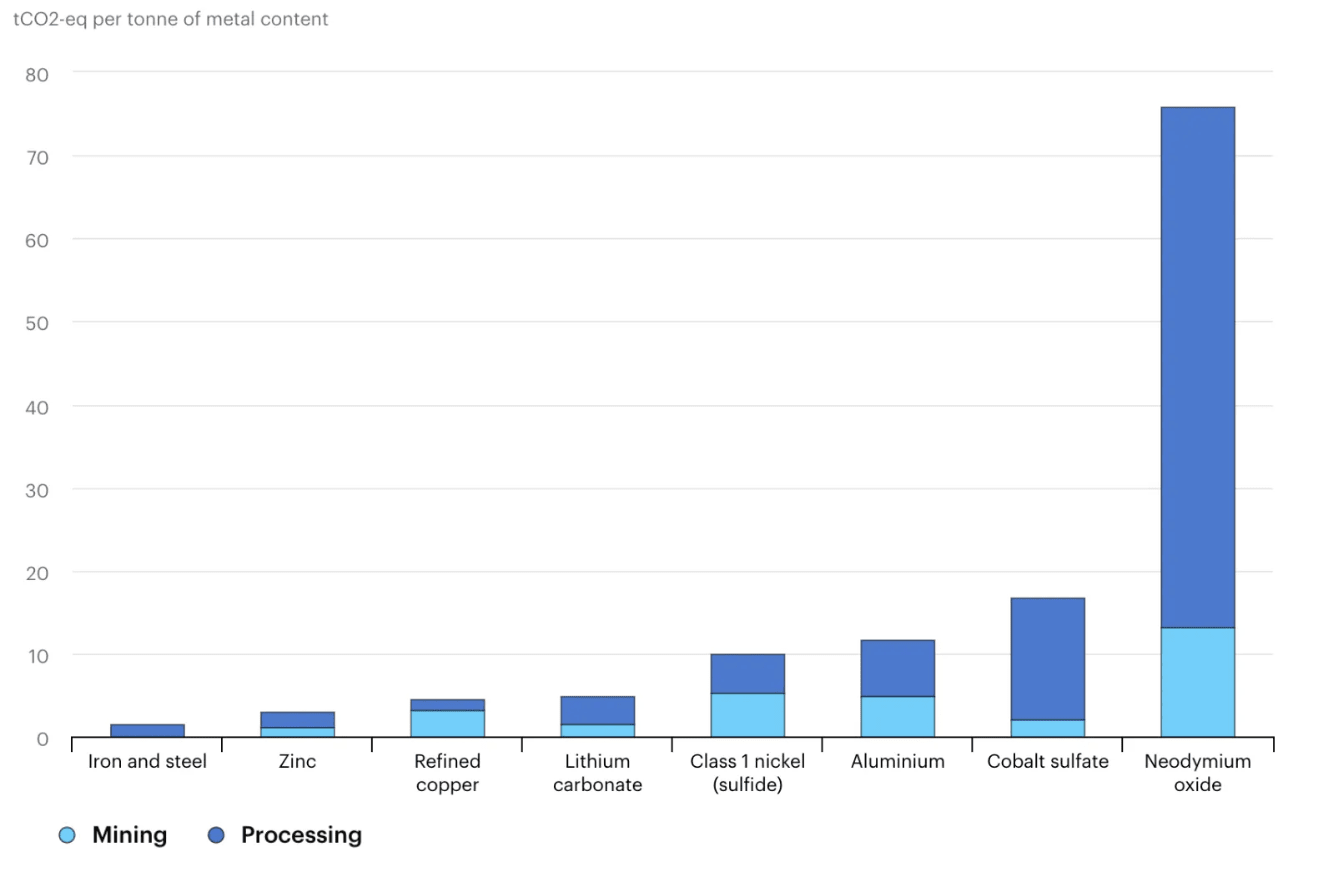

Despite the name, rare-earth metals aren’t actually geologically rare and could, in theory, be mined all over the world. So why have we relied on China for so long despite the obvious risks of doing this? Well, the catch is that mining the most popular rare-earth metal, neodymium, emits miles more CO2 than any other metal (which is ironic because they’re a key ingredient to most green technologies). So, it seems Western countries are choosing to outsource this pollution to quietly keep their hands clean of carbon. This policy naturally snowballed into China having a significant market dominance, allowing it to produce even less common rare-earth elements at an unbeatable cost.

It will be interesting to see how this space shifts. China’s new tariffs could force Western nations to take on the environmental costs of their own rare-earth mines. I’ll be following this story closely over the next few months.

For a brilliant overview of what’s happening, I highly recommend the 11-minute talk Ed Conway gave on Sky News this week.

Thanks so much for reading! If you found this interesting, please consider sharing it and letting us know what you think.

The Potential Surface is a publication exploring the frontiers of science, technology and AI. It is support by Orbital Materials.

Annabella Wheatley runs the Potential Surface, and is a materials scientist and science writer.

.png)