👋 Welcome to Climate Drift: your cheat-sheet to climate. Each edition breaks down real solutions, hard numbers, and career moves for operators, founders, and investors who want impact. For more: Community | Accelerator | Open Climate Firesides | Deep Dives

Hey there 👋

Skander here.

This time, we’re swapping EVs and BESS for a ground-level view: heat pumps and the human chaos of getting them into homes.

Meet Joseph, events veteran turned electrification operator. His obsession? Making heat pumps the default, not the outlier.

In this field report, Joseph walks us through:

🔥 Why heat pumps are the “two-way ACs” we already should’ve adopted

👷 The HVAC contractor dilemma, and why sizing mistakes sabotage performance

🧰 The software closing the gap between models and real-world comfort

📉 The incentive chaos, pricing whiplash, and trust deficit holding back adoption

🚛 The rise of the “heat pump concierge”: startups making it easy, affordable, and climate-friendly

🧠 And how the heat pump moment isn’t a tech problem: it’s a people problem

Forget the shiny climate gadgets. This is a dispatch from the crawlspaces and client calls, where the real heat pump battle is fought with workflows, trust, and way too many oversized furnaces.

🌊 Let’s dive in

But first, who is Joseph?

Joseph DeNatale is a Boston-based small business owner and operator with a background in building and scaling service-driven companies. As the co-founder of a live entertainment agency, he led the development of end-to-end systems that has contributed to 5x growth since 2022, earning a 75% referral rate along the way through thoughtful customer experience design. He is now applying that same operational lens to the home electrification space, with a focus on accelerating heat pump adoption.

This is a long one again, click the title if you want to read it fully 👆

As a small business owner, I’ve built a career not around inventing new things, but around making things happen: making sure systems run smoothly, projects get completed on time, and clients feel taken care of.

My work has been rooted in the real-world, hands-on, often chaotic rhythm of operations, logistics, and direct client service. Whether it’s organizing teams to execute live events, refining workflows to scale a growing business, or managing the delicate art of closing a sale, I’ve learned one simple truth: the hardest part is never the idea. It’s the execution.

So when I began diving into the world of home electrification—particularly heat pumps—that same truth surfaced again, just with higher stakes.

The technology isn’t the issue. In fact, the technology is there. It’s been there for decades, and it is continuing to improve. We’re not waiting on some magical breakthrough or futuristic device.

We’re waiting on people—mostly homeowners and home contractors, but also manufacturers and policy makers—to embrace, understand, and implement what already works.

This piece isn’t about reinventing the wheel. It’s about understanding why we’re not using the wheel we already have—and what it’s going to take, from the human side of the equation, to make heat pumps the obvious, accessible, and default choice for millions of American homes.

In the world of climate solutions, it’s easy to get distracted by what’s shiny and new—sleek devices, breakthrough technologies, futuristic models of sustainability.

But not every climate solution is some new-fangled wonder gadget. Some of them already exist. Some of them are sitting in basements and behind houses, quietly doing the work.

The heat pump is one of them.

Heat pumps are not new. In fact, the idea has been around for well over a century, and the technology has been used widely for decades—mostly in Europe and Asia, but also in pockets of the U.S.—for everything from water heating to whole-home climate control.

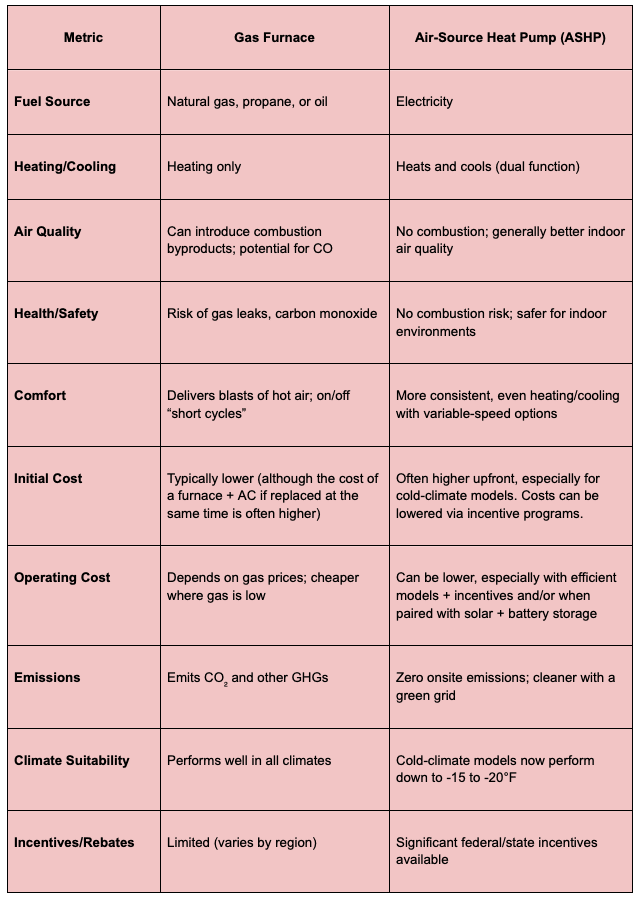

Modern heat pumps are highly efficient—anywhere from 2-4x more efficient than a furnace—and capable of replacing both a furnace and an air conditioner with a single system in virtually every climate. For millions of homes across the country, they offer a cleaner, quieter, and more precise way to stay comfortable year-round.

Importantly, heat pumps have also been shown to match or beat the operating costs of even the cheapest heating option—natural gas—in many cases. This has been demonstrated through both local and national studies. One study showed that over 90% of American households would save on energy bills by replacing worn-out heating equipment with the right-sized heat pump.

Installation costs vary wildly depending on many factors in a home, but with the introduction of generous incentives via the Inflation Reduction Act (IRA) and additional state programs, even these costs can be on-par with fossil fuel alternatives.

So why aren’t they everywhere?

The answer isn’t technical. It’s cultural, economic, and human.

Heat pumps are proven, efficient, and climate-friendly—but adoption is still slow.

The barrier isn’t the tech. It’s people:

Contractors who default to what they know

Homeowners who need education and guidance

A fragmented market full of noise and misinformation

This piece discusses these challenges, and then explores five keys to accelerating adoption:

Educate homeowners so heat pumps feel familiar and trustworthy.

Train the next-gen workforce and upskill legacy HVAC pros.

Leverage better tools and data to size and install systems right.

Prioritize quality and trust to build social proof and demand.

Align policy to phase out one-way ACs and normalize heat pumps.

Execution—not invention—is what will move the needle.

If you’re reading this piece, you probably know what a heat pump is (and you can feel free to skip this section).

But if you’re among the uninitiated – like, believe it or not, most people – here’s a (very) quick primer.

A heat pump works by drawing thermal energy (heat) out of the atmosphere and “pumping” it into the home. This process works in reverse for cooling. (Source)

The term “heat pump”, it turns out, is a fairly unhelpful name for most people. In fact, there are some leaders in the home electrification industry who believe the name itself is one of the barriers to adoption. It’s one of many ways that the heat pump is misunderstood.

Think of a heat pump as a “2-way AC.” An air conditioner cools your home by pulling heat from inside an enclosed space and transferring it outside. Your refrigerator works the same way.

A heat pump does the same thing, but can also reverse the process to bring heat into the home. It uses a few key components to make this happen:

The fan pulls air across the system’s coils to help move heat in or out of the space.

The evaporator coil absorbs heat from the air inside your home (in cooling mode) or from the outside air (in heating mode).

The compressor pressurizes and moves a fluid called refrigerant through the system, enabling the heat transfer process.

The refrigerant is the working fluid that captures and carries heat from one place to another—either out of your home or into it.

What’s important to understand is that a heat pump does not create heat. It also doesn’t create cold (cold is the absence of heat, just like darkness is the absence of light). A heat pump simply transfers – pumps! – heat from one place to another.

“The difference between a heat pump and a one-way AC is just one valve. It still works perfectly fine as an air conditioner—there’s no difference. That’s why we’ve started calling them “two-way ACs” as an education tool. It helps people compare a two-way AC, which has a reverse gear, with a one-way AC—which, in my mind, is basically broken.”

-Shreyas Sudhakar, Founder, Vayu (Heat Pumped Podcast)

But what about in the winter when it’s below freezing? In any environment where the temperature is above absolute zero (remember the Kelvin scale?) there is still a significant amount of heat in the air in the form of thermal energy.

That’s why a heat pump can still heat your home even on the coldest day of the year.

The fact that heat pumps simply transfer heat—and do not create it—gives them the potential to heat homes without doing the thing that humans have done since time immemorial to keep warm: burn stuff.

In the U.S., over half of all homes still rely on burning fossil fuels for heat. Replacing those systems with electric, air source heat pumps (ASHPs) can significantly reduce household emissions, especially as the grid gets cleaner and moves towards a higher percentage of renewable energy (i.e. not burning stuff).

And, because they’re so efficient, heat pumps can lower operating costs over time—although this is highly dependent on where you live, as the cost of fuel and electricity varies widely. They’re also safer (no burning stuff), can improve indoor air quality (again, no burning), and create healthier, more comfortable homes.

Finally, heat pumps are a crucial component of an energy-independent home. Paired with solar panels and battery storage, a homeowner can heat and cool their home entirely with energy they generate on their own. Try that with a furnace!

This is not a marginal climate solution. According to the IEA, global heat pump adoption could reduce carbon emissions by half a billion tons annually—roughly equivalent to the annual emissions of all cars in Europe.

For years, heat pumps were a niche topic, something discussed by green building enthusiasts, early adopters, or homeowners with unusually high energy awareness.

But that’s no longer the case. Here are four reasons why:

The electrification movement is no longer a fringe concept. The push to “electrify everything” has gained traction among policymakers, climate advocates, startups, utilities, and even popular media.

From Substack newsletters to YouTube explainers, there’s growing awareness that building decarbonization—and especially heating and cooling—is one of the most practical, scalable ways for regular people to cut their emissions. Campaigns like Rewiring America’s “Go Electric” initiative frame heat pumps not just as energy-efficient appliances, but as a gateway to modern, climate-aligned homes.

This momentum is turning into real action. Heat pumps have now outsold gas furnaces in the U.S. every year since 2022.

For the time being (Republicans’ “One Big, Beautiful Bill” notwithstanding), both federal and state governments are backing this transition with significant financial and structural support.

The Inflation Reduction Act (IRA) has introduced a suite of rebates, tax credits, and grant programs designed to make heat pumps more affordable and accessible. Single-family households can receive up to $8,000 in upfront rebates for heat pump installations and up to $2,000 in federal tax credits, not to mention additional support for electrical panel upgrades and home energy audits.

State and local governments are also leading the way in the transition away from fossil fuels on both the demand and supply sides. Programs like Efficiency Maine, TECH Clean California, and Mass Save offer generous incentives and no-interest financing to homeowners that drive the cost of electrification upgrades down even further. Meanwhile, New York City has banned gas in new construction, and Massachusetts has ordered public utilities to begin phasing out natural gas, a move which is being studied in at least 11 other states.

The heat pump space is no longer just a niche for contractors and utilities—it’s attracting serious private investment. VC-backed companies like Quilt are reimagining the user experience with sleek, design-forward equipment and app-based controls. Others, like Elephant Energy and Forge, are building “heat pump concierge” platforms that manage the customer journey end-to-end—from sales to install to rebate navigation.

One of the biggest myths about heat pumps—that they can’t handle cold weather—is now being debunked at scale. While older, single-speed models may have struggled in colder temperatures, especially when size and installed incorrectly, modern cold-climate, variable-speed air-source heat pumps can provide reliable heating even at outdoor temperatures of -20°F.

These systems are already in use in northern New England, the upper Midwest, and Canada. In Nordic countries—some of the coldest climates in the word—the technology has been viable for decades.

And yet, despite all this momentum, heat pump adoption is still slow.

Why? Because the hardest part isn’t scaling the technology. It’s aligning the people—contractors, homeowners, policymakers, and market actors—who need to make it happen.

“We’ve had the technology dialed for 20, 30, 40 years, depending on how you’re arguing it—but it’s not being applied. It’s a human problem. It’s not a technical one. The technical one has been solved.”

-Nate Adams, House Whisperer (Heat Pumped Podcast)

That’s where we go next.

If we want to accelerate the heat pump transition, we have to start by understanding the reality on the ground:

Very few people—contractors and homeowners alike—fully understand what a heat pump is, or how it can deliver better comfort, efficiency, and air quality than legacy heating and cooling systems.

That may come as a surprise, especially given another important reality that we’ve already discussed: heat pumps are a viable, high-performance solution in nearly every U.S. climate.

In the sections that follow, we’ll explore the human factors slowing adoption, from the challenges HVAC contractors face on the front lines, to the confusion and mistrust many homeowners bring to the table.

Then, we’ll look at a host of potential solutions, including education, workforce development, improved tools and techniques, and business model innovations.

Let’s start with perhaps the most important link in the chain: the HVAC contractor.

For decades, HVAC (Heating, Ventilation and Air Conditioning) contractors have made their living designing, installing, and servicing the systems that keep homes warm in the winter and cool in the summer. Traditionally, these systems have relied on gas furnaces for heating and central air conditioners for cooling—a familiar, dependable setup that most contractors know inside and out.

The HVAC industry runs on speed, familiarity, and minimizing risk. Systems are often oversized and relatively forgiving, and most replacements are emergencies. That means contractors are incentivized to default to what they know: gas furnaces and central ACs. It's faster, more reliable, and less likely to lead to a callback.

While heat pumps are gaining visibility, limited training, inconsistent results, and a general bias against the technology has made adoption slow. Many in the trade remain skeptical, and understandably so.

To understand the dynamics shaping today’s HVAC industry, it’s helpful to look at a common figure who represents a large portion of the field.

These kinds of contractors fit into an archetype that we can call the “legacy HVAC contractor.”

The legacy HVAC contractor is typically an owner-operator, often a sole proprietor or the head of a small team with a few service technicians. He has built his business over the course of several decades on reputation, reliability, and responsiveness.

From a technical standpoint, his skills and knowledge are “good enough” as far as he’s concerned. He’s not properly trained on “Manual J” (a standardized method for performing a heating and cooling load calculation in a home that we will discuss later in detail), and even if he does complete one prior to recommending a system, he’s probably doing it to satisfy a permitting requirement or regulation.

More often than not, he’s just using a good old “rule of thumb” to determine which heating or cooling equipment is right for which house.

That’s because he almost exclusively installs what he already knows: mostly gas furnaces, maybe central ACs. He’s generally skeptical of any other kinds of equipment, especially heat pumps. If a customer wants one, he’s more than likely to try to steer them back towards a furnace, especially if he’s working in a colder climate.

Why? Because he doesn’t trust that the heat pump is going to provide enough heating on the coldest days of the year. He may have even installed a heat pump for a homeowner in the past—but it did not go well. And the absolute last thing he wants is to get a call from an angry homeowner in the middle of January complaining about how cold their house is.

That would mean he has to make a house call, diagnose a problem with equipment that he may not be overly familiar with, and, worst-case scenario, rip out an under-performing unit and install something new. This costs time—which he doesn’t have—and money.

Furthermore, most customers he works with are calling him because it’s an emergency: their 20 year old gas furnace just quit on them and they’re standing in a frigid basement, staring down the barrel of an unexpected expense that amounts to one of the biggest investments outside of their home and vehicle that they will ever make. They’re emotional, uncomfortable, and they want a solution now.

Enter the legacy HVAC contractor: the trusted (and often only) advisor in the moment of truth, standing in that basement alongside the homeowner, ready to recommend what comes next.

He’s likely going to recommend the lowest risk option, the one that is the cheapest, and the one he knows best: swapping out a like-for-like gas furnace that will almost certainly keep the homeowner warm and will not result in a callback. In fact, he’s probably already got a unit on his truck that he can put in today.

Unless the contractor brings it up, most homeowners will never even know a heat pump is an option—let alone consider it. They’ll simply go with whatever the contractor recommends.

And, to be fair to the contractor, he has good reason to shy away from a heat pump recommendation.

HVAC is one of the most demanding and multidisciplinary trades in the building sector. It draws on elements of electrical work, plumbing, sheet metal fabrication, and refrigeration—all while requiring technicians to perform physically taxing labor in hot attics, cramped crawl spaces, and unpredictable field conditions.

Unlike many other trades, HVAC also demands a solid grasp of science. Technicians must have at minimum a working understanding of fluid dynamics (how air and refrigerants move through ducts and coils), thermodynamics (how heat is transferred and removed), and building science (how air sealing, insulation, and moisture impact comfort and energy use).

And unlike static systems, HVAC systems are dynamic—they respond to weather, ductwork, occupant behavior, and load conditions in real time. That means contractors aren’t just installers; they’re troubleshooters and systems integrators, often diagnosing complex problems under pressure.

To make things even more difficult, most HVAC pros are also running small businesses. The majority operate with fewer than five employees and under $1 million in annual revenue. That means juggling technical work with sales, scheduling, and customer service—often for anxious homeowners in the middle of a heating or cooling emergency.

That downward pressure on a contractor’s time and availability also means that most HVAC businesses aren’t built for long decision cycles. Their business model is optimized for speed, not consultation.

Most contractors are paid to fix problems quickly, not to educate homeowners, spend lots of time understanding the specific problems they are facing in their home, or walk them through the nuances of heat pump performance and rebates. None of these activities are revenue-generating, which means taking the time to recommend a heat pump is not only risky, but also potentially less profitable. The same reasoning applies to larger shops—including those that have been rolled up by private equity.

In that context, it’s no surprise many contractors are risk-averse and skeptical of new technologies like heat pumps, which can feel untested or unfamiliar compared to the like-for-like gas furnace and central AC installations they’ve done for decades.

Unfortunately, following the standard playbook of swapping out like-for-like systems often leads HVAC contractors to do a disservice to their customers that they likely don’t even fully understand.

Let’s take heating as an example. The legacy HVAC contractor, upon entering a customer’s home for an emergency replacement, finds that the customer has a 100,000 BTU (“8-ton”) gas furnace installed that has just broken down on them. Since the customer’s only complaint is that the furnace is no longer working, the easiest and most direct path to solving their problem is to swap out a like-for-like system and install a brand new furnace of the same size.

The problem is that this furnace was never the right size for this home. It was always too big. Studies have suggested that up to 50% of homes in the US have heating systems that are oversized, but reports from the field are even worse:

“95% of furnaces I’ve come across in the field are oversized. Many are two to four times too big.”

-Drew Tozer, Partner, Foundry Heat Pumps (from Feel Good Homes, pg. 18)

When a furnace is oversized, it will still provide heat to the home – but it will do so in short bursts, turning on and off frequently. This is called short-cycling, and it makes the home much less comfortable than it could be. It’s like taking a shower by pouring a bucket of hot water over your head. Frequent short-cycling can also lead to inefficiency, increased energy consumption, and even potential damage.

The same thing can happen with an oversized AC, but there’s an additional negative outcome. When an AC is oversized, it short-cycles just like a furnace does, which may keep the home generally cool. But an AC should also pull moisture and humidity out of the air—and when it turns on and off too quickly, it doesn’t run long enough to properly dehumidify the space.

The result is a home that feels clammy, not comfortable—cool on the thermostat, but sticky and unpleasant in real life. Too much humidity in a home can also cause damage and promote mold growth, leading to a host of poor health outcomes. Setting the thermostat lower to compensate for poor dehumidification can help on the margins, but it will still often result in an uncomfortable home—while using excess energy.

This is typically what happens when a contractor swaps a like-for-like furnace or AC or uses a “rule of thumb” to size a system. These systems “work”—but they often lead to uncomfortable or even unhealthy homes. Oversized systems also cost more to operate.

Here’s the good news: A right-sized, properly installed heat pump will fix essentially all of the problems that oversized gas furnaces and ACs create.

The bad news? Just like with legacy equipment, most contractors do not understand how to properly size heat pumps.

There are a few reasons for this, and it starts with the fact that a heat pump is simply a more complex piece of equipment:

“Rule of thumb worked when you had equipment that did, at most, two things: it either kept your house warm in the winter, or kept it cool and dry in the summer. But as soon as you put in a product that needs to do all three—keep you warm in the winter, and cool and dry in the summer—you’ve increased the complexity exponentially.”

-Ed Smith, Co-founder, Amply (Author Interview)

If a contractor installs an oversized heat pump based only on the size of the existing gas furnace and a general “rule of thumb”, the equipment will almost certainly be oversized for the heating load that the house requires in the winter. And if it’s oversized for heating, it will definitely be oversized for cooling, which will lead to all of the negative outcomes discussed above.

So how do contractors make sure they are right-sizing heat pumps?

Manual J is a standardized method developed by Air Conditioning Contractors of America (ACCA) for calculating how much heating or cooling a home actually needs. It’s meant to replace guesswork with math—taking into account factors like square footage, insulation, window types, and air leakage. This is referred to as a load calculation.

In theory, it’s a critical tool for right-sizing HVAC equipment. In practice, it’s rarely used—and when it is, it’s often done incorrectly. Many contractors either skip it altogether, rely on outdated rule-of-thumb sizing (like BTUs per square foot), or plug in conservative estimates that inflate the heating and cooling loads.

“Contractors often overestimate heating loads. They might make adjustments to the Manual J calculation, or make mistakes, and don’t realize it because the results confirm their expectations. I’ve seen many proposals that are double the actual heating load needed at design conditions.”

-Bruce Harley, Building Science Expert (Author Interview)

The result? Systems that are still too big, too loud, too short-cycling—and still delivering the same problems for homeowners.

When it comes to using Manual J for heat pumps, the problems are no different. If a contractor does complete a load calculation using Manual J, he will often end up with a number that is 2x or higher than the actual heat load of the house. This has been observed over and over again in the field by professionals and is a topic of much debate in building science circles. While the underlying formulas provide precise figures, experienced professionals often find that the results simply don’t accurately reflect real-world conditions:

“The outcomes downstream from the methodology (the outputs from the software) are often wrong. Contractors are using those tools and reaching the wrong answers—even though the underlying formulas are right. Yes, that's often because they're using the calculators wrong… We need to make it easier for contractors to reach the right answer.”

-Drew Tozer, Partner, Foundry Heat Pumps (via LinkedIn)

The upshot? When a contractor overestimates a heating load for a heat pump system, they will often default to recommending a “dual-fuel” system – one that includes a gas furnace for backup heat in the coldest parts of the year – or to simply forget about the heat pump altogether and install a new gas-only system. This leads the homeowner back to square one – burning stuff.

(As an aside: “dual-fuel” systems are not necessarily the worst-case scenario. A system that mostly relies on the heat pump and only switches over to gas in extreme cold can still be hugely beneficial for the homeowner and effective in reducing the majority of their fossil-fuel usage. Some experts in the field even recommend moving to mostly “dual-fuel” systems as a way of easing the transition from gas to electric. But that’s a debate for another time.)

There’s another layer of complexity – many states require contractors to perform a Manual J or equivalent load calculation in order to receive permits and rebates. The result is that contractors often rush the process (or even falsify numbers) just to push projects through, adding more confusion.

So far, we’ve looked at the HVAC contractor – the trusted source making the recommendation in the basement, often under pressure and with limited tools, time, or training to change course. Contractors hold immense power and sway with homeowners, who will ultimately be making the final decision as to how to heat and cool their homes.

But the homeowner’s side of the equation brings its own set of challenges, ones that are equally important in understanding why heat pump adoption still lags.

For most homeowners, HVAC is a black box. 86% of U.S. homeowners lack detailed knowledge of their HVAC system. They often don’t know how it works, or even understand the full scope of the equipment they have in their home. They just want to be comfortable, especially in an emergency, which is unfortunately when the vast majority of HVAC installs are completed.

When the furnace dies in the middle of winter, they’re not researching variable-speed inverter technology or weighing decarbonization benefits. They’re cold, stressed, and looking for the fastest fix. That often means relying entirely on the contractor standing in front of them.

But what kind of information do they actually want or need?

Most people have no idea how their house is heated or cooled. Frankly, they don't care. I think a lot of the industry is focused around buzzwords and efficiency numbers and all of these things. But for most people, it's like, is my house warm? No? I need to get it fixed.

-Shreyas Sudhakar, Founder, Vayu (Author Interview)

It turns out that—big surprise—most people don’t even want to know how their HVAC system works. They don’t want to have a discussion about BTUs or a 2-ton vs a 3-ton system. They just want to avoid getting more overwhelmed than they already are, feel confident about their decision, and be comfortable in their home.

This limited understanding puts the homeowner in a vulnerable position when it’s time to choose a contractor for a new installation or replacement. Lacking the technical expertise to evaluate system design or installation quality, many default to more relatable metrics: courtesy, friendliness, and responsiveness. Was the contractor polite? Did they take off their shoes when they came in the front door? Did they return my call quickly?

But courtesy isn't the same as competence. And when a homeowner can’t tell the difference between high- and low-quality work, they often fall back on the most important metric they do understand: price.

“If homeowners can't tell the difference between good and bad equipment and good and bad contractors, they just pick the cheapest one every time. We call it the race to the bottom. It's that the cheapest bid wins – and there's always a cheaper contractor.”

-Drew Tozer, Partner, Foundry Heat Pumps (Author Interview)

This dynamic hurts everyone. It rewards speed over precision, discourages proper system design, and turns the sales conversation into one about price rather than value.

In short, it commodifies work that should be customized.

And in an emergency replacement scenario, the odds of any kind of nuanced conversation between the contractor and the homeowner are slim:

“The homeowner is just focused on getting the heat back on. So this very big, very expensive decision ends up being compressed into just a few hours, maybe a day at most. That leaves no room for a bigger conversation about other options, especially when the average homeowner hasn’t heard of a heat pump.”

-Drew Tozer, Partner, Foundry Heat Pumps (Author Interview)

In this scenario, there’s not much of an opening for a contractor to educate a distressed homeowner on the benefits of choosing a heat pump, even if that contractor wanted to do so. In the end, it's homeowners who pay the price in the form of oversized systems, higher energy bills, and uncomfortable homes.

Let’s say that a motivated homeowner and their contractor do have a conversation about installing a heat pump. One of the most common—and most confusing—questions they will ask is: “What’s this going to cost me?”

Unfortunately, the answer is rarely straightforward.

Heat pump pricing varies wildly. There’s a mix of factors at play: system type, installation complexity, local labor rates, contractor business models, and whether ductwork needs to be added or upgraded.

For instance, a study by Laminar Collective gathered quotes from 15 different contractors for both ductless mini-split systems—wall-mounted units that deliver heating and cooling without ductwork—and ducted systems, which connect to a home’s existing central air ducts. The test case: a 1,500-square-foot, 3-bedroom home in Wakefield, MA.

The results are staggering. Ductless systems averaged around $29,000, but quotes ranged from under $20,000 to over $40,000. Ducted systems averaged $38,000, with bids spanning from under $25,000 to over $50,000—an astonishing 100% difference from low to high for both systems.

Massive price discrepancies like these are not uncommon. This undermines homeowner confidence and makes it nearly impossible to know what a “fair” price actually is.

It’s an understatement to say that the incentive landscape for home electrification is confusing. Even in a relatively stable policy environment, homeowners face a dizzying array of programs at the federal, state, local, and utility levels, each with its own eligibility rules, paperwork, deadlines, and equipment requirements.

For example: a homeowner in Boulder, CO looking to install a heat pump and take advantage of rebates has to navigate all of the following:

“There’s a rebate from the city of Boulder. There’s a rebate from Boulder County. There’s a rebate from the utility. There’s a state tax credit. There’s a federal tax credit. There’s just a huge amount of incentives—but you have to choose the right equipment to make sure you qualify for those incentives.”

–D.R. Richardson, Co-founder, Elephant Energy (Climate Action Homes)

And if you live just a few miles away, across a city or county line, the available rebates could look completely different—even if you're still within the same utility’s territory.

The sheer number of programs, combined with inconsistent eligibility criteria, makes it nearly impossible for the average homeowner to figure out how much money they can actually save or what steps they need to take to qualify. Many incentives require specific equipment types, certifications, or pre-approval processes. Miss one detail, and you could lose out on thousands of dollars.

Unfortunately, many legacy HVAC contractors are also in the dark when it comes to taking full advantage of incentives. They don’t have the capacity to take on the additional administrative burden of tracking constantly shifting rebate rules, managing paperwork, or helping homeowners apply for tax credits. It’s simply not within the scope of their business model.

In many regions, this leaves homeowners with few options if they want a contractor who can help them navigate available incentives.

Between lack of information and guidance, inconsistent pricing, and confusing incentives, it’s no wonder many homeowners either delay upgrading their systems or fall back on the status quo, even when better solutions exist.

If we want heat pump adoption to scale, we have to fix these human problems. In the next section, we’ll look at the solutions starting to break through.

Now that we’ve covered challenges to heat pump adoption, we turn to solutions.

The good news is that none of these barriers are insurmountable. In fact, a growing number of HVAC pros, startups, nonprofits, and policymakers are already rolling up their sleeves and making real progress.

What follows are practical, scalable ways to move the needle—solutions that close the information gap for homeowners, address the workforce bottleneck, and rewire the systems that shape how heating and cooling decisions get made.

Many homeowners are in the dark (or worse, misinformed) about heat pumps. They’ve heard myths that heat pumps “don’t work in cold weather” or will jack up their electric bill. They might not know about incentives or how to find a quality installer.

This knowledge gap leads to hesitancy and sticker shock, and it lets low-cost, low-quality contractors win jobs that end in disappointment.

In short, uninformed consumers = slow heat pump adoption.

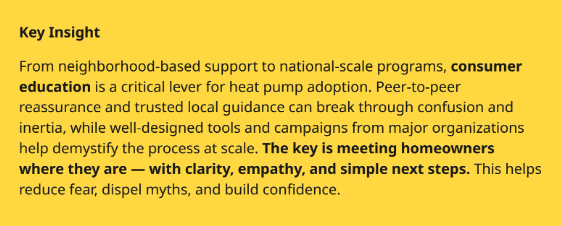

One of the most effective ways to combat misinformation is through peer-to-peer education. When someone hears about a heat pump from a friend, neighbor or local homeowner they trust, it makes the idea more tangible and less intimidating. The key is meeting people where they are: usually overwhelmed, confused, and looking for reassurance.

Go Electric Colorado is a nonprofit community organization helping homeowners make sense of home electrification. Founded by local residents motivated to decarbonize their lifestyles, the organization guides fellow residents through the maze of incentives, technologies, and decisions through community events, one-on-one coaching, and educational campaigns.

That kind of peer-to-peer model can make a huge impact:

“Every homeowner I talked to [about heat pumps] had the same experience. They found it really overwhelming. They were super confused and they just didn't know what to do. They didn't even need to learn things – just feel a little bit less overwhelmed [and] validate the feeling that a heat pump is a good thing. Because there's lots of people telling you heat pumps are bad. And then, just give them one or two next steps to cut through all the noise. [You’ll have] 100% success rate on people finding that valuable. Does it get them all to actually go install a heat pump the next day? No. But it just shows how low the bar is. There's so much low hanging fruit to accelerate this transition.”

-Will Greenbohl, Board Member, Go Electric Colorado (Author Interview)

While grassroots efforts are crucial, large organizations are also stepping up to educate consumers and streamline the path to electrification. These major players are developing tools, programs, and resources to make heat pump adoption more accessible and understandable.

Rewiring America is a nonprofit focused on electrifying homes and communities across the U.S. They offer a suite of tools to demystify the process:

Incentive Calculator: A user-friendly tool that helps homeowners identify available tax credits and rebates for electrification projects, including heat pumps.

Personal Electrification Planner: This planner provides tailored recommendations based on a homeowner's specific circumstances, outlining steps to transition to electric appliances and systems.

Electric Coaches Program: A training initiative that equips community members with the knowledge to guide others through electrification decisions, fostering peer-to-peer support networks.

The Building Decarbonization Coalition (BDC) is working to shift the cultural narrative around electrification by making clean electric homes feel desirable, not just responsible.

Consumer Inspiration Initiative: Uses storytelling, visual design, and lifestyle branding to make home electrification relatable and aspirational.

Switch is On Campaign: Offers videos, homeowner guides, and simple explanations to help everyday people understand the benefits of heat pumps and other electric upgrades.

Ambassador Program: Trains homeowners, contractors, and community leaders to serve as local electrification advocates—answering questions, sharing personal stories, and helping others get started.

Mass Save, a collaborative initiative by Massachusetts' electric and gas utilities, offers comprehensive programs to guide homeowners through energy-efficient upgrades.

No-Cost Home Energy Assessments: Homeowners can schedule in-person or virtual assessments where Energy Specialists evaluate energy usage, identify inefficiencies, and provide personalized recommendations. These assessments often include the installation of energy-saving products at no cost.

Rebates and Incentives: Mass Save offers substantial rebates for heat pump installations—up to $10,000 for whole-home systems and up to $16,000 for income-eligible customers.

0% Interest HEAT Loans: Through the HEAT Loan Program, homeowners may qualify for 0% financing up to $25,000 for energy-efficient upgrades, including heat pumps.

Northeast Energy Efficiency Partnerships (NEEP) is a regional nonprofit that works to accelerate energy efficiency in the Northeast and Mid-Atlantic.

Consumer Resources: Provides guides and tools to help homeowners understand and select appropriate heat pump systems for their needs.

Cold Climate Air Source Heat Pump (ccASHP) Specification: Develops and maintains a product list to ensure consumers and contractors have access to high-performing heat pump models suitable for colder climates.

Market Transformation Strategies: Collaborates with stakeholders to promote policies and programs that support the adoption of energy-efficient technologies.

Arguably the most powerful teachable moment is the sales visit in a customer’s home. The contractor’s comfort advisor or salesperson has a prime opportunity to enlighten (or unfortunately, to confuse or mislead) the homeowner.

Part of the solution is training contractors how to educate customers as part of their process. This benefits both the customer and the contractor. The customer gets a better understanding of their home and how the right equipment can maximize its performance. The contractor gets to sell on value rather than on price and avoid the “race to the bottom” trap:

“Without education, the customer is going to look for the lowest price. So using building science, we were able to show the customer that they had problems [in their home]. The customer knew they had problems—they just didn't know there was a measurement to identify those problems. Once we tied in the building science and actually gave that customer education, we were able to show them those additional problems. At the same time, that presentation separated us from other contractors. So building science—the education piece with the customer—has been huge. It's been a success for our business.”

-Brynn Cooksey, Founder, Air Doctors Heating and Cooling, LLC (The Heat Pump Podcast)

By educating the client, the contractor builds trust and often justifies a higher price because it comes with real solutions, not just swapping out like-for-like equipment. In doing so, he can sidestep the “race to the bottom” that plagues most legacy contractors.

Unfortunately, many contractors will decline to do this—opting instead for the easy, reliable path of swapping out like-for-like equipment, thus perpetuating the cycle of poor performance, continued fossil fuel use, and the “race to the bottom.”

But those that do will have a powerful lever to differentiate their businesses while shifting the conversation from cost to outcomes. This builds long-term customer loyalty and stronger word-of-mouth—an invaluable advantage in a commoditized industry that will also result in more high-performance, decarbonized homes.

Educated customers are more likely to be satisfied customers, which means better word-of-mouth for heat pumps overall. Informed homeowners make smarter decisions, prioritize quality over price, and often become vocal ambassadors for the technology.

Just as the EV adoption curve went through a period of misinformation, skepticism, and growing pains before reaching mainstream acceptance, heat pumps are on a similar path. The more we equip consumers with knowledge, the faster we move through that curve—turning early adopters into educators and accelerating the transition for everyone.

“I hear a lot of people saying, ‘if clients actually asked me for the right stuff, I’d do that.’ So I’m going to try and help the clients actually ask for the right stuff”

-Nate Adams, The House Whisperer (The Heat Pump Podcast)

As we’ve discussed, one of the biggest obstacles to heat pump adoption is a shortage of contractors who are comfortable installing them. Even among experienced HVAC techs, many haven’t had the chance to get hands-on training with modern heat pump systems.

That’s a problem—not just because it slows adoption, but because a poorly installed heat pump can perform worse than a fossil fuel system. And when that happens, people talk. It erodes trust and reinforces outdated myths.

Fortunately, there are a slew of solutions coming from both inside and outside the industry.

Some forward-thinking contractors are making training a core part of their company DNA. Forge, based outside Boston, is tackling the labor shortage head-on by recruiting young talent and training them quickly on heat pumps.

Forge is one of a number of young “heat pump concierge” companies (a business model we’ll discuss further in a bit) that aim to make transitioning to a heat pump an easy choice for homeowners. But Forge stands out—they’re vertically integrated and have built their own internal training academy with the express mission of expanding the skilled trades workforce.

The urgency is real. The average HVAC professional is 54 years old, and many are expected to retire within the next decade. There are simply not enough “bodies in trucks”—and there will be even fewer if nothing changes.

That’s why Forge is investing in the next generation. By focusing on bringing Gen Z into the trades, they’re not only bridging the heat pump knowledge gap that plagues legacy contractors, they’re also rebuilding the pipeline of skilled labor from the ground up:

We found that from a training perspective, heat pumps are a really great way to take someone and get them trained up quickly to do a skilled trade. We bring people into our workshop, do a concentrated training session, then pair them up with highly experienced crews in the field. To start, they’re the “third man” on a crew – learning and doing support work. Depending on the person, after six months or a year or two years, they’re no longer the third man on the crew—they’re the second—and they’re doing the real work in the field.

-Olivia Loycano, Head of Sales & Marketing, Forge (Author Interview)

Forge doesn’t charge for training, and aims to hire everyone who goes through their training program. The results speak for themselves: in just 18 months, this venture-backed startup went from zero to over 10 installation crews in Massachusetts, all while maintaining high quality results.

If that kind of rapid scaling sounds unusual in HVAC, that’s because it is. It’s the kind of growth typically associated with software startups, not construction companies.

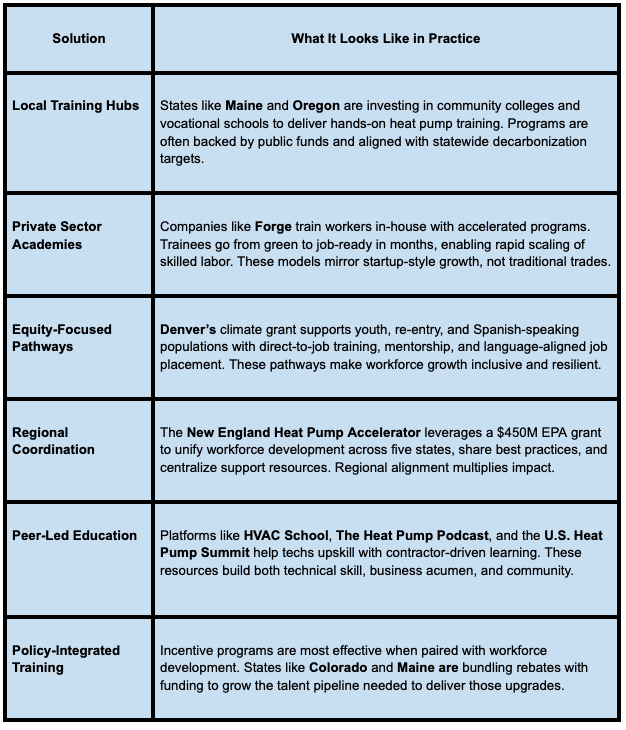

As heat pump adoption surges, a nationwide public policy push is on to train an army of HVAC pros who can install and service these systems. From New England to the Pacific Northwest, initiatives are springing up to bridge the skills gap.

Tiny Maine has become a big inspiration for heat pump adoption and a case study in how workforce development can keep up with policy ambition. Back in 2019, Maine set a goal of 100,000 new heat pump installations by 2025. Surprise: they hit the mark two years early, prompting Governor Janet Mills to up the target by another 175,000 heat pumps by 2027.

A flagship effort is the heat pump training lab at Kennebec Valley Community College, launched in 2021, which has already trained over 300 students in installation and maintenance. Meanwhile, Efficiency Maine – the quasi-state agency overseeing efficiency programs – has poured over $400,000 into heat pump and weatherization training at KVCC and supports 29 similar programs at other Maine institutions each year.

The Governor’s Energy Office, through a Clean Energy Partnership, has also awarded nearly $5 million in grants for clean energy training since 2022, reaching 3,500+ participants statewide. This is all in service of Maine’s larger goal of training 30,000 clean energy workers by 2030.

In mid-2024, the Denver Regional Council of Governments (DRCOG) won a $199 million EPA Climate Pollution Reduction Grant to fund a comprehensive building decarbonization program across the region. A big chunk of this grant will fuel coordinated initiatives that reduce building emissions, foster workforce development, and provide rebates for electric appliances like heat pumps and efficient water heaters.

The program is projected to train over 4,800 workers in clean electrification trades – including upskilling 1,000 existing workers into new specialties. Additional resources include programs to scale small heat pump focused businesses and a “heat pump agent” program that will provide free administrative support to assist businesses in navigating rebates and other paperwork.

Finally, DRCOG will support a number of equity-driven programs, including training currently incarcerated individuals with a pathway to direct placement post-incarceration, programs taught entirely in Spanish with placement in language-aligned firms and homes, and youth programs with afterschool mentorship opportunities.

Out West, Oregon is tackling the talent gap head-on with a new $2 million Energy Workforce Training Program. Rolled out by the Oregon Department of Energy in late 2024, this initiative aims to prepare both new and existing tradespeople for the state’s aggressive building decarbonization goals – 500,000 heat pumps to be installed by 2030.

The program funds community colleges, technical high school programs, trade unions and more to provide training in four key areas: HVAC systems, home energy auditing, contractor business development, and efficient home upgrades. This training will help contractors properly size equipment and deliver quality installations.

Launched with a massive $450 million EPA grant in 2024, the New England Heat Pump Accelerator is a five-state coalition (MA, CT, RI, NH, ME) designed to “supercharge” the move from oil and gas furnaces to electric heat pumps.

The program’s to-do list is ambitious: incentivize manufacturers to bulk up heat pump supply, help low- and middle-income households afford installations, and set up a central resource hub to share data and best practices in adoption and workforce training. Notably, at least 40% of the funding is earmarked for disadvantaged communities, including support for workforce training and community-based heat pump programs.

Along with additional funds and workforce development programs from Northeast Energy Efficiency Partnerships (NEEP), the region is well-situated to make a sizeable dent in residential decarbonization over the next decade.

As heat pump adoption gains ground, the HVAC industry is stepping up with better training, more peer support, and accessible education. A new wave of platforms and events is helping contractors stay ahead of the curve—not just technically, but also in how they run their businesses.

HVAC School has become a go-to resource for technicians nationwide. With a mix of podcasts, how-to videos, and hands-on content, it’s one of the few platforms offering free, practical education for working techs. The annual HVACR Training Symposium offers presentations on a number of topics in HVAC and building science, including an increasing number of heat pump-related discussions.

Meanwhile, the U.S. Heat Pump Summit, now in its third iteration, is creating space for contractors to learn from one another. The event offers both technical and business training in an environment focused specifically on heat pump adoption.

Also contractor-focused, Amply Energy’s Heat Pump Podcast shares interviews with forward-thinking professionals across the country—from high-performance builders to small business owners. The podcast is a living library of best practices, hard-won lessons, and business models that work.

A big component of these resources involves getting HVAC contractors up to speed on basic building science—an area historically siloed from the HVAC trades but increasingly essential to high-performance installations.

“We need better cross-pollination between HVAC and home performance industries. HVAC contractors should understand the basics of building science—like how a bit of insulation or sealing up huge attic leaks can improve comfort and the success of the heat pump installation. Even things like sealing return ducts embedded in wall cavities that are effectively open to the outdoors—a furnace might be oversized and still work under those conditions, but a heat pump won’t perform well unless you fix the problem.”

Bruce Harley, Building Science Expert (Author Interview)

With more training programs, better resources, and community support, the contractor base can grow in both size and competence. The bottom line is that heat pumps should become a standard part of every HVAC professional’s skill set, not a niche specialty.

With contractors and consumers both climbing the learning curve, the next piece of the puzzle is giving them the tools and data to make smart decisions.

As discussed earlier, designing and installing heat pump systems can be technically complex. One of the most important steps that a contractor needs to take to right-size a heat pump system for a home is to complete a load calculation, which helps determine how much heating or cooling a home needs.

The Manual J load calculation method was designed to bring rigor and accuracy to HVAC sizing—but in practice, it’s often ignored, misused, or manipulated. Many contractors either skip it or fudge the numbers, leading to oversized systems and poor performance. Worse, inflated load calculations frequently steer homeowners toward gas systems or dual-fuel setups, undercutting electrification goals.

Manual J Barriers

Historically, contractors have relied on “rules of thumb”—like calculating BTUs based on square footage—to perform quick and simple load estimates. The alternative was far more time-consuming: taking detailed measurements of every room, assessing insulation levels, and manually inputting data into spreadsheets or even paper-based calculators. For most contractors, especially when swapping out a gas furnace was the norm, that level of effort simply wasn’t worth it.

But heat pump systems are different. These old shortcuts often lead to oversized equipment that performs poorly or even fails. Fortunately, there are several alternative approaches that can lead to more accurate load calcs without a huge amount of effort.

Software To The Rescue

Software tools from companies like Amply Energy and Conduit use real-time LiDAR scanning and AI to generate accurate 3D models of a home, saving contractors hours of manual data collection. Augmented reality features allow quick visual design mock-ups, helping homeowners understand system layout like mini-split head locations or duct placement.

Critically, the software produces ACCA-certified Manual J reports, giving contractors precise heating and cooling load calculations while satisfying permitting and rebate requirements. Additional capabilities include auto-importing publicly available property data, setting climate-specific design conditions, customizing the building envelope, and producing clear design documents for both homeowners and installation teams.

These tools not only help contractors speed up their load calculation considerably, but also create an opening to have a more in-depth discussion with the homeowner.

If someone was doing it the right way before—where they were going in, taking out a laser tape measure, hand-drawing a 2D floor plan with all the dimensions, and then later going back to enter all of that into WrightSoft to do a really good load calculation—that’s a four-hour exercise. We take about 15 minutes. So we’re much, much, much faster than the old right way. And we’re radically better in terms of accuracy.

What a bunch of our customers find is the homeowner follows them around because the scan is kind of captivating—like, 'What are you doing?' It becomes a great conversation piece. So really, the 15 minutes are just interwoven with this great opportunity to get to know the customer, get to know their priorities, and build the right system the right way

-Ed Smith, Co-Founder, Amply (Author Interview)

Contractors who leverage these tools can produce more accurate load calculations, save significant time, and shift the sales conversation toward outcomes and long-term value—rather than just price. But there’s a catch: without a solid understanding of Manual J fundamentals, even the best software can lead to flawed results. As the saying goes, “garbage in, garbage out.”

It’s worth noting that the Manual J methodology is currently under review by ACCA, with an emphasis on the “survey” component of the process—the data that contractors need to collect in the field. The hope for the industry is that the updates will reduce inconsistencies and create a more reliable, streamlined process that delivers more accurate results and clearer guidance for contractors.

Performance-Based Heat Loads

There’s another way to achieve a load calculation that has nothing to do with energy models like Manual J, and some professionals believe it’s an essential step in the process.

Models give the illusion of accuracy, but there is no way to know if the output is accurate without comparing the results to real-world performance.

-Drew Tozer, Partner, Foundry Heat Pumps (Feel Good Homes, pg. 95)

A performance-based heat load uses real-world data from the existing heating system in the home to accurately and reliably size the equipment for the new system. As outlined in Drew Tozer’s book Feel Good Homes, there are two methods of using performance data:

Method 1: Energy Consumption

This method looks at a home's actual energy consumption—typically from heating fuel or electric bills—paired with local weather data to estimate how much heat the home truly needs. By converting fuel usage into BTUs and analyzing it relative to outdoor temperatures, contractors can calculate a more accurate heating load based on real-world conditions rather than theoretical models. This method relies on consistent historical data and can underestimate needs if the home was underheated or supplemented with other heat sources.

Method 2: Runtime Data

This refers to how long an existing furnace operates over a period of time. This data can be used to estimate a home’s actual heat load by tracking how often and how long the furnace runs at the design temperature (typically the coldest days of the year). By analyzing this data—especially during the coldest periods—contractors can infer how much heat the system is delivering to maintain indoor temperatures. If the furnace short-cycles frequently during extreme cold—for instance, running for only 30 minutes over the course of an hour—that indicates that the system is oversized (by two times, in this example). A right-sized system would run at close 100% capacity at the design temperature.

Energy consumption is typically easier to get than runtime data because almost every homeowner can scare up some old gas bills, whereas some homes don’t have equipment (either the furnace or the thermostat) that provides accurate data. Needless to say, both of these methods only work for retrofits where an existing system is being replaced.

Performance-based data can be used to verify a Manual J load calculation by serving as a real-world cross-check against the modeled heating load. If the energy use or runtime data shows significantly lower heating demand than the Manual J suggests, it may indicate the calculation was overly conservative.

One company that is operationalizing performanced-based heat loads is Thermentor. Their software product analyzes a home’s actual energy consumption and local weather data to estimate heating and cooling loads. It interprets utility bills and combines them with temperature data to produce actionable design metrics and even estimates future bill impacts.

Additionally, Thermentor flags available rebates and incentives based on the proposed system, helping contractors present everything clearly to homeowners. By comparing actual performance to predicted loads, contractors can catch oversizing errors, justify smaller, more efficient equipment, and design systems that better match the home’s true needs.

Once a contractor has an accurate load calculation, the next step is to choose the right heat pump to match that load. In order to maximize the homeowner’s savings on electricity bills, he needs to choose a heat pump that is right-sized in terms of capacity (BTUs) but also efficiency.

SEER (Seasonal Energy Efficiency Ratio) and HSPF (Heating Seasonal Performance Factor) are two standard metrics developed by AHRI (Air-Conditioning, Heating and Refrigeration Institute) used to measure the efficiency of HVAC systems. The ratings are determined by lab testing done by the manufacturers, and certain equipment must meet minimum efficiency standards as required by DOE.

The problem is that the efficiency ratings often don’t reflect how heat pumps actually perform in real homes. The lab tests are done under controlled conditions and the results are plugged into a computer model that estimates seasonal performance. But that model is based on climate assumptions and test points that don’t line up with how most systems run day to day.

All of these tests are conducted at fixed compressor speeds and fixed fan speeds... it’s a test mode and has little to do with how the system actually operates in real life.

-Bruce Harley, Building Science Expert (Load-Based Testing of Heat Pumps, 2024)

The discrepancy between lab-testing data and real-world performance is more than academic, and it affects more than just efficiency. Chasing ultra-high SEER ratings (higher = more efficient) can sometimes come at the cost of comfort. Some equipment achieves impressive SEER numbers at the expense of humidity control – but unless a contractor has tested that equipment themselves, they would have no way of knowing this:

We don’t require manufacturers to publish latent performance [humidity]… and we’re allowed to slap these things in. There are multiple mini-split manufacturers who have absolutely no performance data for latent capacity… How do I know which one to pick? You don’t.

-Alex Meaney, Mean HVAC (The Heat Pump Podcast)

This can lead to a range of negative outcomes, from mild discomfort—like a home that feels cool but clammy—to more serious issues, such as hidden moisture buildup and mold growth. The tradeoff between efficiency and performance isn’t obvious to the homeowner—or even to many contractors—unless more granular performance data is available.

One potential solution comes in the form of load-based testing. Unlike conventional lab tests that fix indoor and outdoor conditions to evaluate performance under idealized settings, load-based testing simulates real-world dynamics. One testing methodology, developed in collaboration by a series of international working groups led by the Canadian Standards Association (CSA), applies a virtual building load to the system in a controlled laboratory environment, letting the equipment respond using its built-in algorithms—just as it would in a real home.

With a load-based test, you're measuring the heating or cooling capacity of the equipment in real time as it's running. And you're basically saying, I'm going to create a simple model of a building in the lab, that has energy coming in or out through the enclosure, and you're letting the equipment try to match that energy (with the opposite sign) by providing cooling or heating.

-Bruce Harley, Building Science Expert (Load-Based Testing of Heat Pumps, 2024)

Instead of testing fixed speeds and conditions, the load-based method continuously adjusts the heating or cooling demand depending on outdoor temperatures. This simulation allows for more complete and accurate data about how a heat pump will perform across a realistic range of scenarios.

The result is performance data that’s far more representative of what a homeowner will experience, helping contractors make better design decisions and reducing the risk of oversizing or misapplication.

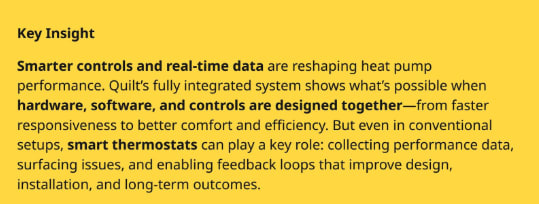

If real-world performance data and smarter system design are the future of home heating and cooling, there’s one company that’s already building that future into every unit they ship.

Founded in 2022, Quilt is a vertically integrated OEM building ductless heat pump systems with software, connectivity, and user experience baked into every layer of the product.

Rather than relying on third-party thermostats or outdated controls, Quilt’s system is designed as a complete stack: hardware, software, and user interface all working together. This allows their equipment to operate as a true smart system—able to sense, adjust, and optimize in real time.

Unlike traditional thermostats, which have no insight into what's happening inside the unit, Quilt’s system knows exactly what speed the compressor is running, the temperature of the coils, and how fast the fans are spinning. With this data, it can intelligently modulate performance to balance efficiency and comfort based on conditions in the home.

“A Nest or Ecobee [thermostat] doesn’t know what speed the compressor is, it doesn’t know the temperature of the coils in the outdoor unit, and it fundamentally can’t…. Because we’ve integrated it, we can build algorithms that work across all those data points and optimize specifically for the hardware we’ve created.”

-Paul Lambert, Founder, Quilt (The Heat Pump Podcast)

At the core of this system is an unusually powerful onboard computer—reportedly over 1,000 times more capable than the chips in typical mini-splits—enabling sophisticated algorithms to run continuously.

The result is not just higher efficiency, but better lived experience: consistent temperatures, faster response times, and reduced energy waste. This is especially impactful in homes with varying thermal loads, where traditional systems struggle to maintain even comfort.

In short, it’s the Cadillac (or Tesla) of heat pumps.

Quilt may be the gold-standard for a completely optimized, data-based system, but there is still plenty of room for improvements in all kinds of heat pump systems using a real-world, performance-based data approach.

Smart thermostats can serve as a valuable bridge by collecting runtime data, tracking temperature trends, and detecting patterns that reveal performance issues or inefficiencies. Paired with cloud connectivity and analytics, they can provide both homeowners, contractors, and even utilities with powerful insights:

“I’ve been very vocal about begging power companies… to just buy a butt-ton of thermostats that contain data loggers. And instead of the incentive program being “We’ll give you free stuff if you let us shut off your air conditioner on the hottest day of the year”... instead, trade it for the data. Data trumps everything. Field data—like actual house field data—not this computer model BS. Like, we lived in this house, we had data loggers, this is what happened.”

-Alex Meaney, Mean HVAC (The Heat Pump Podcast)

While they may not have full visibility into equipment internals like Quilt’s system, smart thermostats can still enable basic diagnostics, trigger alerts, and help fine-tune control strategies while creating a trove of performance data—all steps toward a more responsive, efficient home heating experience.

What’s more, with enough anonymized data points, we could refine our understanding of what causes heat pump failures or inefficiencies.

For example, by analyzing hundreds or thousands of installations, algorithms might detect that homes of a certain style in Climate Zone 5 consistently struggle to maintain setpoint when winds are high, which could lead to better sizing recommendations or envelope fixes.

In short, feedback loops from field data will help continuously improve both technology and installation practices.

There is one significant caveat: there is evidence that suggests that third-party smart thermostats should only be used with non-variable speed heat pumps. When used with variable-speed units, third-party thermostats generally don’t support proper operation in variable-speed mode, and it has been shown that their use results in on/off cycling behavior that greatly reduces efficiency.

One solution? Smart thermostats provided by the OEM and natively integrated with the unit, as such products become available.

Designing better heat pump systems requires moving beyond outdated rules and unreliable sizing. New tools—from advanced software to performance-based methods and smart controls—offer faster, more accurate, and data-driven ways to match equipment to real-world home needs. Better tools and data are force multipliers for the trained workforce and educated consumers we discussed earlier.

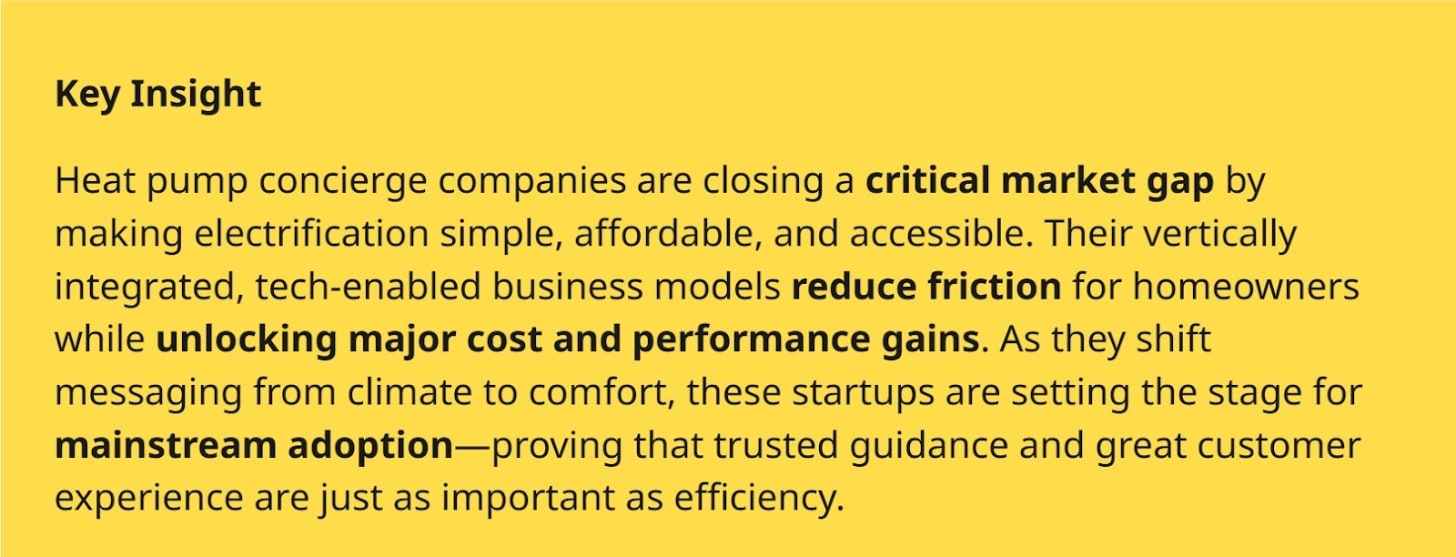

The complicated, often confusing process that homeowners looking to switch from gas heating to electric systems often face represents a gap in the HVAC market. In response, a new category of businesses has emerged to fill this need. These companies are increasingly known as “heat pump concierge” services.

These companies act as one-stop guides, managing the entire heat pump journey from education and planning to installation and ongoing support. They often work with vetted crews, handle all permitting and paperwork, secure rebates, and ensure system performance.

Some also offer additional electrification services—such as induction stoves, EV chargers, heat pump water heaters, and weatherization—enabling a full-home transition. By streamlining every step, they remove the friction that typically holds homeowners back, making the process simple, affordable, and appealing.

By owning more of the process end-to-end than a traditional HVAC company would, concierge startups can streamline operations and even pass savings on to consumers. For example, Jetson found that vertical integration – working with an OEM to produce its own heat pump units – plus a tech-driven installation process can cut consumer costs by up to 90% after rebates.

Similarly, Boston-based Tetra redesigned the buying process with instant online quotes and automated workflow management, yielding cost savings of up to 30% compared to typical contractors. These efficiencies attract venture funding and fuel rapid growth.

The early success of many of these businesses has been driven by venture capital investments. Elephant Energy, a Colorado-founded concierge provider, raised $5.8 million since 2021 to expand beyond its home market, and Tetra recently secured a $10.5 million round to support bi-coastal expansion.

By combining homeowner education, incentive capture, and streamlined business models, “heat pump concierge” companies simplify the buying process and can significantly reduce upfront costs. This is a powerful lever—cost parity with traditional systems changes the conversation entirely. If a heat pump costs the same or less than a gas furnace, runs more efficiently, lowers energy bills, and delivers a cleaner, healthier, more comfortable home, it becomes the obvious default.

A notable divergence among these companies is how they market the benefits of electrification to customers. Broadly, two go-to-market messaging strategies have emerged:

Climate/Decarbonization-First Messaging

Many electrification concierge startups lean into an environmental pitch, seeking to attract the climate-conscious early adopters. Elephant Energy and Jetson are prime examples.

Elephant’s entire brand is built around “climate-friendly homes” – the company frequently cites the carbon emissions avoided by its projects and urges homeowners to stop “burning stuff” to heat their homes. Similarly, Jetson identifies “replacing outdated fossil-fuel systems” as a key component of its mission and emphasizes how switching to a heat pump can drastically cut a home’s emissions.

This climate-forward messaging resonates with sustainability-minded consumers and early-adopters while giving these startups a distinctly mission-driven identity. It’s also a powerful tool for attracting talent and investors who prioritize climate impact.

But companies like Elephant and Jetson don’t rely on climate appeals alone—they link the green narrative to tangible homeowner benefits like cost savings, comfort, and cleaner indoor air, making the case both values-driven and practical.

Comfort, Health, and Value Messaging:

Other companies downplay the climate talk and instead sell heat pumps as a lifestyle upgrade – a better product for the homeowner’s comfort, safety, and wallet, installed by true experts.

Foundry, a Toronto-based heat pump installer, focuses its messaging on comfort, health, and safety—emphasizing that heat pumps are “the only system that can be properly sized to match the needs of the house.” Foundry also draws a clear distinction between traditional contractors, who service all types of HVAC systems, and its own specialized technicians, who work exclusively on heat pumps.

Similarly, Forge brands itself as “the heat pump experts,” spotlighting the systems’ versatility and cost benefits rather than leading with their climate impact. The company also highlights its fully in-house technician model—not subcontractors—and leans heavily on quality customer service as a key differentiator.

While this messaging is designed to broaden the appeal beyond the eco-aware niche, the fact remains that many of the homeowners reaching out to these “heat pump concierge” companies already have some understanding of the technology and its climate benefits—and that’s a primary motivator:

“We’re only based in Massachusetts, so for the people we consider our target audience, the environmental benefits of a heat pump are appealing. But I think there will come a time—maybe a year from now, maybe five, or even ten years—when everyone who cares deeply about the environment already has a heat pump. At that point, we’ll need to start expanding beyond that group.”

-Olivia Loycano, Head of Sales & Marketing, Forge (Author Interview)

This is the next phase of heat pump adoption: reaching beyond early adopters. Once the climate-conscious and home efficiency enthusiasts are on board, the challenge becomes engaging homeowners who aren’t already invested in sustainability.

But before we can get there, we need to ensure every homeowner has a great experience—from education to installation to long-term performance. They need to feel comfortable in their home and confident in their choice. That’s what will ultimately allow heat pumps to thrive.

If you’ve gotten this far—first of all, congratulations! You must really be PUMPED about heat pumps (sorry, couldn’t resist).

By now, it should be clear: heat pump adoption in the U.S. is at a critical inflection point. The technology is solid. The benefits are clear. But cultural inertia, misinformation, and complexity are still slowing things down.

To accelerate adoption, we need to focus on the following key goals:

Make heat pumps an easy, obvious choice for homeowners.

That starts with education and trusted guidance. Community groups, national platforms, and “heat pump concierge” companies all play a vital role. The more consumers understand what a heat pump is—and how it can improve their comfort, lower their bills, and reduce emissions—the more confident they’ll be in making the switch. Even small shifts in language, like referring to heat pumps as a “2-way AC,” can make the technology feel more familiar and approachable.

“70% of our time is spent in our homes – not just indoors, but in our actual house. And HVAC is the biggest factor [that determines] whether your house is going to be comfortable or uncomfortable. It has such a huge impact on our quality of life. So I'm trying to get homeowners to think about HVAC as a tool to solve those problems and improve their homes rather than just ignoring it for as long as possible until it breaks.”

-Drew Tozer, Partner, Foundry Heat Pumps (Author Interview)

We’ve seen this play out before: early EV adoption was bogged down by skepticism, range anxiety, and myths. Over time, familiarity and visible benefits (plus improvements in the technology) helped turn the tide. The same can happen with heat pumps—and it should be even easier, because the technology is already fully viable in virtually every climate. But it will only happen if we meet people where they are and make the experience simple, affordable, and rewarding.

If you have a heat pump in your home and you love it—tell your neighbors, tell your family, tell your friends. Host a party and showcase your heat pump in action. Become a heat pump advocate in your local community!

Build the next-gen heat pump workforce

We must expand the pool of skilled heat pump system designers and installers. As a new generation replaces the aging HVAC workforce, it’s essential that they’re equipped not just with the technical skills to properly size and install heat pumps, but also free from the skepticism and outdated assumptions that have held the industry back.

Investing in training programs—whether through trade schools, public initiatives, or private companies—is key. Every new tech trained in heat pumps isn’t just another installer; they’re a front-line ambassador who can confidently recommend the technology to homeowners and deliver high-quality results, thus accelerating demand.

Upskilling legacy HVAC pros is another key component, but this won’t be easy. There are nearly 150,000 HVAC establishments in the U.S, with most being small, family-owned businesses. Even as trade organizations begin to promote heat pump adoption, they simply don’t have the reach to rapidly shift behavior across such a fragmented market.

That’s why consumer education is so critical. As homeowners learn to ask for heat pumps by name, market demand will push contractors to adapt—or risk being left behind.

Leverage better tools and data

We also have an opportunity to modernize the way heat pumps are sold, installed, and monitored through new tools, data, and diagnostics. Software like Amply can make right-sizing and commissioning faster, more accurate, and more transparent, cutting down the time to produce an accurate heat load-calculation from hours to minutes and opening the door to a conversation with the homeowner that focuses on value over cost.

But modeling tools, if used incorrectly and in isolation, risk leading to bad sizing and bad outcomes for homeowners. That’s why we also need to standardize performance-based heat loads, using either energy consumption or runtime data. Pairing each heat pump with a smart thermostat—and incorporating the use of that data into service and maintenance contracts—will allow heat pump-focused companies to build feedback loops, improve outcomes over time, and close the gap between modeling and real-world performance.

Prioritize quality and build trust