Palitsyn Evgenii/Shutterstock

Your car needs electricity. You don't have mice striking flint in your engine's combustion chambers, nor do you have kerosene lamps for headlights. You might be able to hire a string quartet to replace your radio, but good luck fitting a cello in the backseat of anything but a panel van. Even an 1885 Benz Patent-Motorwagen needed to generate a spark somehow, and Karl Benz used a battery combined with a trembler coil ignition system. But a little battery isn't going to cut it when people want to turn on high beams and crank some tunes. In 1912, Cadillac debuted the first car with a whole electrical system and self-starter. That groundbreaking starter had a second function: generating electricity.

Surprisingly, as advanced as the 1912 Cadillac was, it wasn't the first car with a generator, though people generally called them "dynamos," which was the style at the time. Ferdinand Porsche (yes, that Ferdinand Porsche) built a car called Semper Vivus ("Always Alive" in English) with a combustion engine that drove a generator to power electric motors in the wheels.

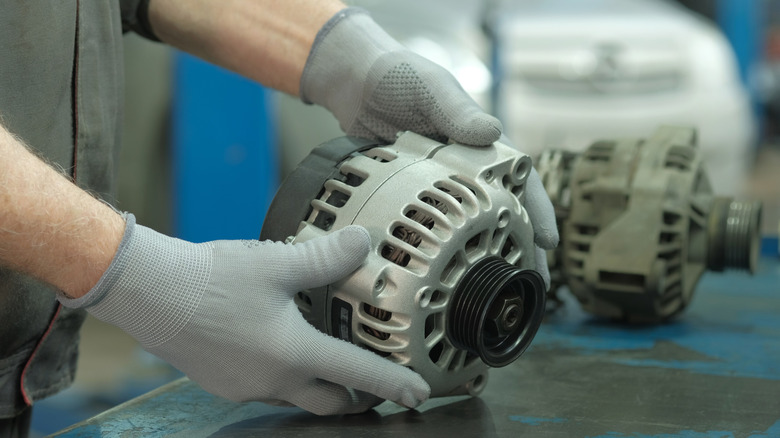

But dynamos/generators of the era had a major problem: they were super unreliable and dependent on engine rpm to produce decent voltage. Using generators was necessary because they produce DC current, which is what cars need to power the stuff we like. Alternators are more efficient, simpler to produce, and have far greater durability, but they only produce AC current. So, manufacturers sucked it up and made do. What changed the game was WWII pushing the development of silicon diode rectifiers, which could cheaply and reliably convert AC (alternating current) to DC (direct current). Chrysler introduced the first automotive alternator in the 1960 Plymouth Valiant, and cars finally had a durable method of electricity production.

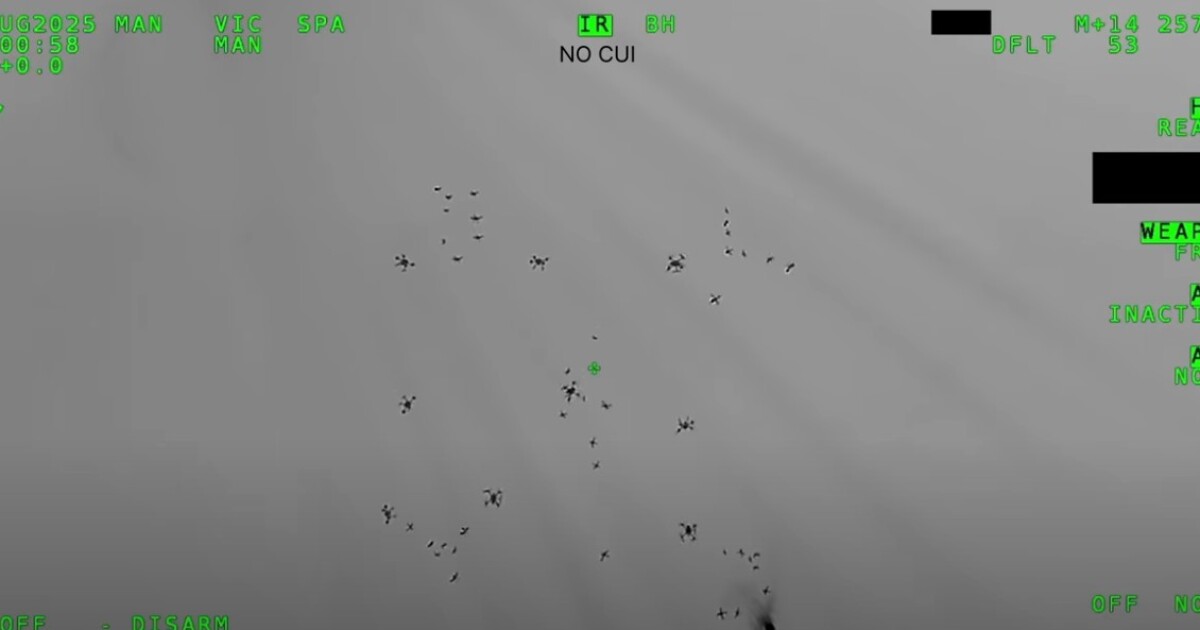

Peering inside the generator to gaze upon its flaws

To understand why generators aren't up to the task, let's break one open and look at its most important parts: the stator and the rotor. The stator is a stationary set of coil windings. Encased within it is the rotor, which, unsurprisingly, rotates. The resulting magnetic field induces electricity, and the current passes to a commutator, a ring of copper with little gaps in it to prevent shorts in the coil. The commutator spins between carbon brushes, which transfer the current to the electrical system.

Physical contact between the brushes and the commutator is the main problem. First, brushes will wear out and need replacement. Also, the faster the generator spins, the more likely the brushes will actually lift away from the commutator and fail to transfer electricity. But don't worry, it gets worse. There's a decent amount of contact resistance between brushes and commutator. Spinning a generator too fast increases heat and builds up voltage, causing the solder that holds everything together to melt, hence the old-timey term "throwing the solder." That's bad, by the way, as it ruins the generator. Now, an alternator can go out while you're driving, too; it's just far less likely.

In 1962, T.G. Wilson and P.H. Trickey invented brushless DC motors, which then led to brushless DC generators. By this point, DC generators were unneccessary, because Chrysler had already solidly rectified the state of power generation in cars with solid-state rectified alternators. Interestingly, guitar amplifiers had been using vacuum tube rectification since the 1930s. Perhaps if Leo Fender were more of a car guy, he could have wired up a tube-rectified alternator instead of making rock and roll possible with his tweed-covered amps.

AC/DC: which one is better for those about to drive?

Yagi Studio/Getty Images

If alternators are so great, let's just make cars use AC! Well, no, that's actually not desirable. DC's smooth, uninterruped electron flow is exactly what automotive systems need for consistent operation. AC works well over long distances, while DC suffers loss as it travels, but this doesn't matter in a tiny car. Nikola Tesla and Thomas Edison famously warred over which is better, and Westinghouse sided with Tesla and AC because it was more appropriate for the country's power grid. By the way, Edison never electrocuted an elephant to prove AC was dangerous. "Topsy" the elephant was put down because she killed someone, and the Society for the Prevention of Cruelty to Animals thought it would be humane to put her down via poison, strangulation, and electrocution (yes, all at once). Edison, by no means a flawless guy, wasn't involved.

Even brushless DC generators are still less efficient than rectified alternators. Alternator coils are connected directly to the output points because their stators transmit electricity rather than the rotors. Alternators spin up faster, output is smoother, and they generate more low-rpm power. Plus, alternators have three sets of stator windings rather than one, and output three times the energy from the same amount of rotation.

But, as awesome as alternators are, even they may become antiquated. Already, hybrids don't use alternators, and instead use a DC-DC converter. Electric cars obviously have no alternator, either. As for internal combustion engines, PyroDelta Energy is working on a thermoelectric generator, which uses heat differential to make power, preventing parasitic drag on the powertrain. Researchers are even working on a device that straps to a regular old tailpipe to turn waste heat into energy. No word on any teleportation advancements, though.

.png)